lw compressors, hydrogen compressor for sale, lw compressor, lw americas, americas compressors

Benefits of High-Pressure Compressors

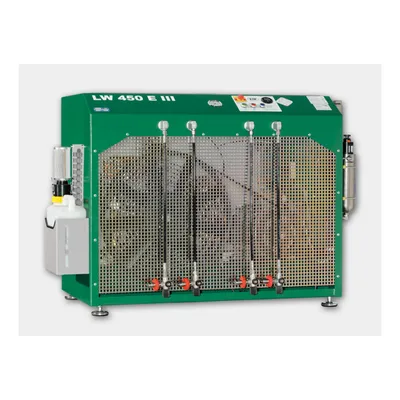

High-pressure compressors offer numerous advantages across various applications, including enhanced efficiency, reliability, and safety. These compressors are designed to operate continuously, providing a steady supply of high-pressure air for critical uses such as diving, firefighting, and industrial processes.

For instance, in the diving industry, high-pressure compressors ensure a safe and reliable supply of breathing air, allowing divers to perform their tasks confidently. Additionally, their robust design minimizes downtime, making them ideal for industries that require constant air supply, such as medical facilities and emergency services.

Choosing the Right Compressor for Your Needs

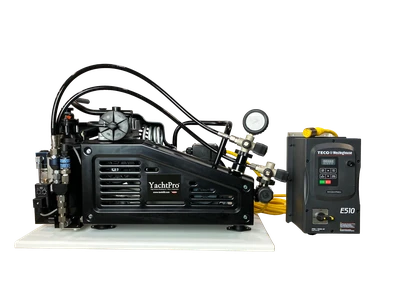

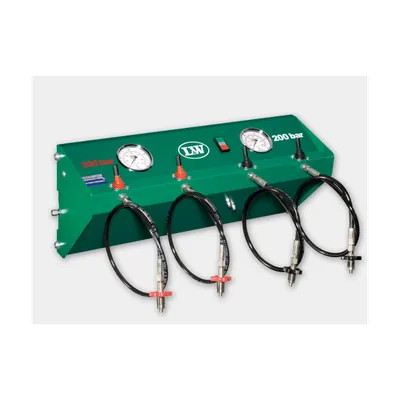

Selecting the appropriate high-pressure compressor is crucial for achieving optimal performance and safety in your specific application. Factors to consider include the required pressure levels, air quality standards, and the intended use of the compressed air, whether for recreational diving or industrial applications.

For example, a diving operation might prioritize compressors that can fill tanks quickly while maintaining air purity, whereas an industrial application may focus on compressors that provide consistent output under heavy load. Consulting with experts can help ensure you select a compressor that meets your operational demands effectively.

Maintenance and Care for Compressors

Regular maintenance of high-pressure compressors is essential to ensure their longevity and reliability. Proper care includes routine inspections, oil changes, and filter replacements to prevent potential failures and maintain optimal performance.

For instance, neglecting maintenance can lead to increased wear and tear, resulting in costly repairs or downtime. Establishing a maintenance schedule and following manufacturer guidelines can significantly extend the life of your compressor and ensure it operates safely and efficiently.

Innovations in Compressor Technology

The field of high-pressure compressors is continually evolving, with innovations aimed at improving efficiency, reducing noise, and enhancing safety features. Recent advancements include the integration of smart technology for real-time monitoring and automated adjustments to optimize performance.

For example, some modern compressors now feature IoT capabilities that allow users to track performance metrics remotely, ensuring timely maintenance and operational efficiency. These innovations not only enhance user experience but also contribute to lower operational costs and increased safety in various applications.