Description

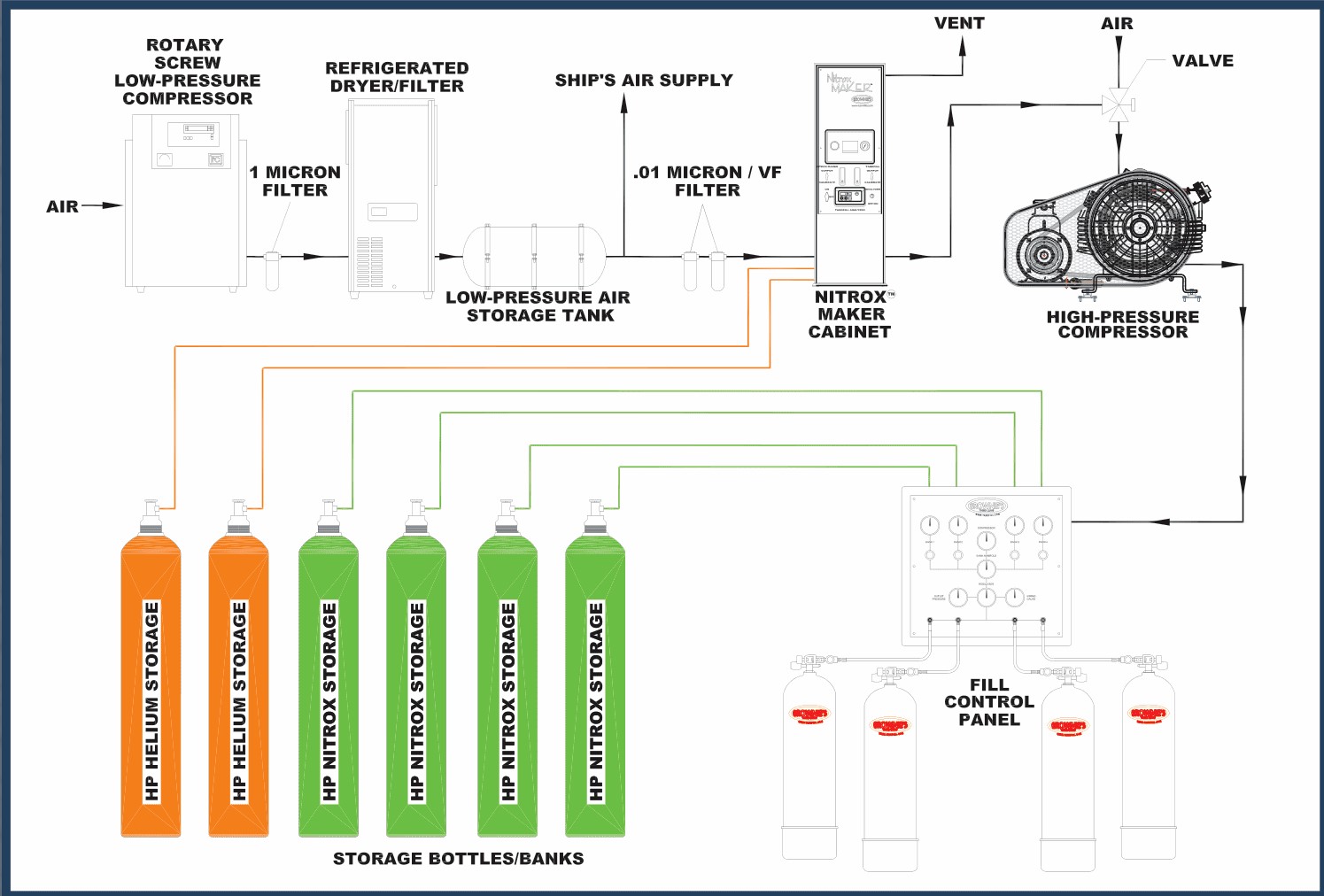

Brownie’s NitroxMaker™ is an easy-to-use nitrox station designed specifically for yachts. This system is capable of producing and analyzing nitrox mixtures from 21%-40% with the turn of a dial. Simply choose the appropriate mixture and the NitroxMaker™ produces the gas using a high-efficiency semi-permeable membrane system that operates at a remarkably low temperature. This method of nitrox production eliminates the need to carry bulky and potentially hazardous cylinders of pure oxygen onboard.

Additionally, by utilizing a membrane that does not require high-temperature heating for stabilization or efficiency, potential damage to the high-pressure compressor is avoided. The NitroxMaker™ can be integrated with the medium duty YachtPro™ 45 and the full line of heavy duty YachtPro™ compressors.

This makes nitrox generation available to a wide range of vessel sizes and configurations.

The Rotary Screw Low-Pressure Compressor

- Provides the gas that will flow through the NitroxMakerTM. It is precisely matched to the size of the HP compressor and is capable of providing ship’s air for other applications if necessary.

The Refrigerated Dryer/Filter

- Removes impurities and moisture to ensure only the highest quality air flows through the system to the NitroxMaker™.

The Low-Pressure Air Storage Tank

- Provides the volume of LP air necessary to drive and maintain the needed pressure for the NitroxMaker™..

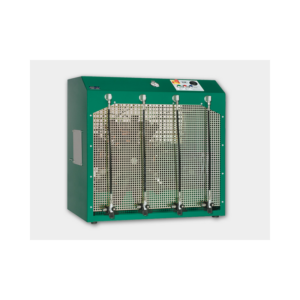

The NitroxMaker™ Cabinet

- Is where the operator designates a desired nitrox mixture up to 40%. Clean air from the LP compressor is converted into nitrox, analyzed and displayed digitally to ensure accuracy.

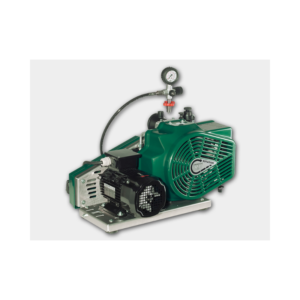

The High Pressure Compressor

Pumps either ambient air or nitrox from the NitroxMaker™. up to 5000 psi for use in scuba tanks and air storage systems.

Storage Bottles/Banks

- Are high-capacity tanks designed for storing large volumes of gas including air, nitrox, trimix and helium.

The Fill Control Panel

- Directs the flow gas from the high-pressure compressor to storage bottles and/or fill whips. Precise controls allow for efficient “cascade filling” of tanks.