What is a High Pressure Air Compressor? Complete Guide 2026

High pressure air compressors are mechanical systems that raise ambient air to high pressure levels—typically hundreds to thousands of PSI—to supply breathing air, fill pressure vessels, and power specialized equipment. This guide explains what a high pressure air compressor is, how multi-stage compression and cooling produce clean compressed air, and why pressure rating (PSI) and flow rate (SCFM) are the defining performance metrics. Readers will learn the main compressor types, the internal components that determine reliability and safety, the sector-specific applications from diving to medical use, best practices for maintenance and operator safety, energy-efficiency innovations current in 2026, and the primary cost drivers buyers should weigh. The article integrates practical comparison tables, checklists, and selection tips to help engineers, procurement professionals, and operations managers match compressor specifications to real-world needs. Throughout the guide we use semantic relationships—like pressure → determines → flow capability—to clarify trade-offs and to help you specify the right solution. To discuss further, you can contact the LW Americas team.

What are the main types of high pressure air compressors?

A high pressure air compressor refers to machines built to generate elevated pressure levels above typical industrial low-pressure systems; major categories include reciprocating (piston), rotary screw/scroll (rotary), cascade-stage assemblies, and dedicated breathing-air units optimized for air purity and safety. These types differ in mechanism, duty cycle, and best-fit applications: reciprocating units deliver high PSI in intermittent bursts, rotary units provide steadier continuous flow at moderate high pressure, cascade systems stack stages to reach extreme pressures, and breathing-air compressors include advanced filtration and controls for safe human use. Understanding these categories helps match pressure rating and flow to tasks like scuba tank filling or high-pressure testing. Below is a compact comparison to guide initial selection and to support featured-snippet style quick decisions for buyers.

This table highlights how compressor selection is driven by required PSI and the flow profile; the next subsections explain mechanical trade-offs and customization features that refine these broad categories.

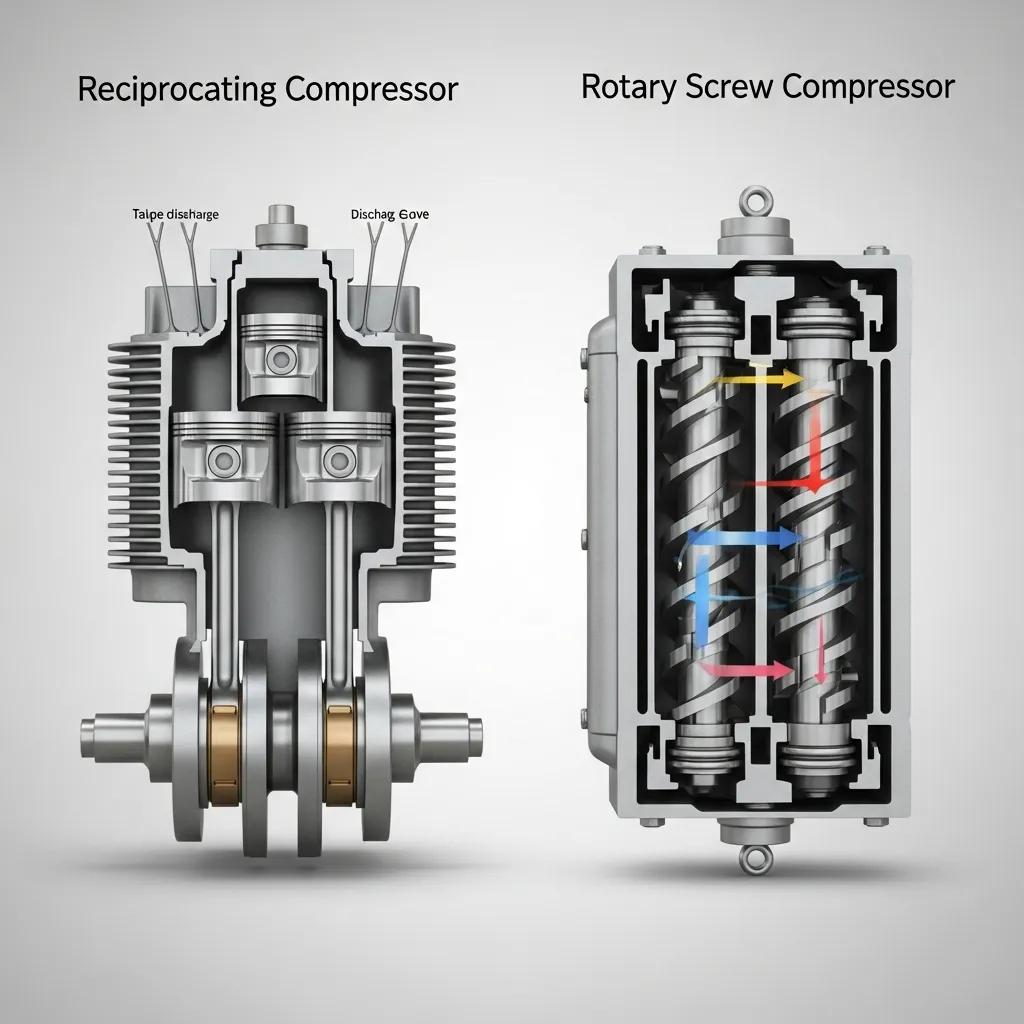

How do reciprocating and rotary compressors differ?

Reciprocating compressors compress air via pistons and cylinders, generating high pressures in discrete strokes; rotary compressors use meshing screws or scroll elements to trap and compress air continuously. Reciprocating units typically achieve higher maximum PSI per stage and are well suited to intermittent, high-pressure fills where duty cycles are moderate, whereas rotary designs favor continuous duty with smoother flow and lower vibration. Maintenance trade-offs are notable: reciprocating machines need more frequent valve and ring work and routine piston inspections, while rotary units require attention to bearings, seals, and oil-system health; both demand proper cooling and filtration. Understanding these mechanical differences helps procurement teams weigh lifecycle maintenance, operational duty cycle, and the specific failure modes that affect uptime and total cost of ownership.

What are the features of custom high pressure compressor solutions?

Custom high pressure compressor solutions allow specification of staging, materials, filtration trains, and control systems to meet exact pressure, purity, and footprint requirements for specialized sectors. Customization areas include corrosion-resistant materials, multi-stage intercooling and aftercooling arrangements, breathing-air-certified filtration stacks, integrated control panels with remote monitoring, and skid or containerized packaging for maritime or mobile use. Choosing custom over off-the-shelf is appropriate when standard models cannot meet required PSI/SCFM combinations, air quality standards, or space and environmental constraints; custom engineering reduces integration risk and ensures compliance with sector-specific operational needs.

LW Americas, a specialized provider of high pressure air compressor systems and custom engineered solutions, can configure staging, filtration, and controls to match sector-specific needs when off-the-shelf options are insufficient. Their approach focuses on reliability, compliance, and support for diving, firefighting, maritime, medical, and industrial customers.

How does a high pressure air compressor work?

A high pressure air compressor works by drawing in ambient air, increasing its pressure through one or more mechanical compression stages, cooling and filtering the compressed air between stages, and finally delivering stored or continuous high-pressure air to the application. Mechanically, the process follows intake → staged compression → intercooling/aftercooling → filtration/drying → storage or direct delivery, and each step affects temperature, moisture content, and particulate loading that must be controlled for safe downstream use. Controls and safety interlocks regulate stage sequencing, pressure relief, and system shutdowns to prevent overpressure and to maintain air quality; well-designed systems also include instrumentation to verify PSI and SCFM performance. The bottom-line benefit is reliable high-pressure delivery matched to the application with minimized heat and contamination through staged cooling and effective filtration.

To clarify component roles and maintenance implications, the table below maps core components to function and performance impact.

This component breakdown shows how each meronym contributes to performance and why a holistic maintenance program is essential. The next section examines pressure and flow relationships that determine how a compressor performs on the job.

What are the key components and pressure ratings?

Key components in a high pressure compressor include cylinders/pistons (or rotary elements), valves, intercoolers, aftercoolers, filtration stacks, pressure vessels, and a control panel with safety interlocks. Pressure ratings are usually specified in PSI or bar and may indicate maximum discharge pressure, working pressure, or test pressure; multi-stage compressors often specify per-stage pressures and the final combined output. Single-stage designs suit lower high-pressure requirements, while multi-stage compressors distribute compression across stages to control temperature rise and improve efficiency; selecting appropriate safety margins and relief setpoints is essential for safe operation. Always interpret pressure ratings in the context of the intended use—breathing air fills require certified processes and filtration to ensure air quality alongside the correct PSI.

How do pressure and flow rate affect compressor performance?

Pressure (PSI) and flow rate (SCFM or m³/h) are linked: higher target pressure often reduces available flow for a given compressor size, and increased flow demands can require larger displacement or additional stages to hold pressure. When specifying equipment, match the required SCFM at the operational PSI rather than a disconnected nominal flow value; oversizing for peak demands or providing buffer storage can smooth intermittent high-flow events. A simple worked example helps: if a task needs a 2000 PSI fill at 10 SCFM sustained, choose a compressor whose rated SCFM at 2000 PSI meets or exceeds that requirement, or provide cascade staging to maintain fill times. Properly matching pressure and flow preserves efficiency, reduces cyclical stress on components, and extends service intervals.

What are the primary applications of high pressure air compressors?

High pressure air compressors serve sectors that require concentrated high-pressure air or certified breathing air: diving (scuba fills), firefighting (SCBA cylinder fills), maritime systems (shipboard breathing and control systems), medical-grade air supply, industrial testing and pneumatics, and sports uses such as paintball or compressed-air sports. Each sector imposes specific requirements—breathing-air purity and redundancy for diving and firefighting, corrosion and vibration resistance for maritime applications, and regulatory or medical-grade filtration for clinical environments. Understanding application-specific air quality and duty-cycle expectations ensures correct compressor type, filtration, and backup systems are specified.

The following list summarizes common sectors and concise examples of how compressors are used in each.

- Diving: High-pressure cascade systems and breathing-air filtration for cylinder fills that meet breathing-air standards.

- Firefighting: Mobile or fixed fill stations for SCBA cylinders with emphasis on rapid turn-around and redundancy.

- Maritime: Shipboard systems require compact, vibration-tolerant compressors with corrosion-resistant materials.

- Medical: Medical-grade compressed air for respiratory applications requiring strict filtration and backups.

- Industrial & Testing: Pressure testing, high-pressure pneumatics, and specialty manufacturing processes that use elevated PSI.

These application profiles highlight why air purity, fill-time, and redundancy are frequent selection drivers. The next subsections provide deeper examples and explain how operational constraints shape equipment choices.

How are compressors used in diving, firefighting, and maritime sectors?

In diving, compressors often appear as cascade filling systems with multiple storage cylinders to rapidly fill scuba tanks while maintaining breathing-air purity via multi-stage filtration and monitoring. Firefighting operations require portable or fixed fill stations that can service SCBA bottles quickly and repeatedly, emphasizing redundancy, fast fill rates, and certified breathing-air filtration for first responders. Maritime installations prioritize compact footprints, low-vibration mounting, and corrosion-resistant materials to survive saltwater environments while delivering reliable high-pressure air for emergency breathing systems and control functions. Each sector imposes design trade-offs—portability versus continuous throughput—that influence whether reciprocating, rotary, or cascade systems are best suited to the mission.

What roles do compressors play in medical and industrial fields?

In medical environments, compressors supply clean, dry, and reliably regulated air for respiratory therapy and instrument operation; filtration, backup systems, and rigorous maintenance protocols are central to compliance and patient safety. Industrial roles include providing high-pressure pneumatics, powering endurance testing rigs, and delivering compressed air for processes that require elevated PSI or precision control; duty cycle and integration with plant controls are the primary engineering considerations. For both medical and industrial uses, selecting proper filtration, monitoring, and service agreements determines long-term uptime and compliance. Addressing those requirements at specification time reduces risk and simplifies lifecycle support.

LW Americas has experience building tailored systems for diving, firefighting, maritime, medical, and industrial customers, combining custom staging, filtration stacks, and packaging to meet sector-specific operational and air-quality expectations.

What are the best practices for high pressure air compressor maintenance and safety?

Effective maintenance and safety for high pressure air compressors rest on scheduled inspections, routine service tasks, component testing, and robust operator training to prevent overpressure events and maintain air quality. A recommended approach combines daily visual checks, weekly functional inspections, monthly filter and fluid reviews, and annual pressure-vessel and relief-device testing; documented procedures and certified technicians minimize risk and downtime. Safety-critical features include pressure relief valves, redundant sensors and alarms, interlocks to prevent unsafe operation, and accessible emergency shutdowns; maintaining these systems through regular testing is non-negotiable.

Below is a practical maintenance checklist presented as actionable items, followed by a short summary of safety standards and operator training considerations.

- Daily Visual & Operational Checks: Verify gauges, alarms, oil levels, and listen for abnormal noises.

- Weekly Filter and Drain Management: Inspect and service filters; drain condensate from separators and receivers.

- Monthly Lubrication and Belt/Seal Inspection: Check oil condition, belt tension, and seals for leaks.

- Annual Pressure Vessel & Relief Valve Testing: Perform certified inspections and test relief devices per regulations.

How often should maintenance be performed and what does it include?

Maintenance frequency depends on duty cycle and application criticality but follows a layered schedule: daily operational checks for leaks and abnormal operation, weekly or biweekly filter and condensate management, monthly oil and mechanical inspections, and annual system-level testing of pressure vessels and safety devices. Core tasks include filter element replacement, oil analysis and changes, valve inspections, intercooler and aftercooler cleaning, relief-valve testing, and calibration of control and monitoring systems; breathing-air systems additionally require documented air-quality testing. Signs of wear—rising temperatures, reduced flow at rated PSI, or oil contamination—should trigger immediate inspection to prevent cascading failures. A formal maintenance log and assigned responsible parties ensure accountability and a clear record for audits and warranty claims.

What safety features and standards are essential for operation?

Essential safety features include pressure relief valves sized and set appropriately, redundant pressure and temperature sensors tied to automatic shutdown logic, audible and visual alarms, and interlocks that prevent operation outside safe parameters. Operator training on emergency shutdown, leak response, and routine safety testing is critical; documented emergency procedures and regular drills reduce incident severity. While specific certification names are beyond this guide, verify that breathing-air systems and pressure vessels are serviced to recognized standards and that maintenance personnel follow accredited training programs. Incorporating these safety features and enforcing procedures protects people, equipment, and regulatory compliance.

How do energy efficiency and innovations impact high pressure air compressors?

Energy efficiency and recent innovations significantly reduce operating expense for high pressure air compressors by improving load matching, recovering waste heat, and enabling predictive maintenance that minimizes downtime and unnecessary runtime. Contemporary technologies in 2026 include variable frequency drives (VFDs) and advanced controls for precise load-following, enhanced sealing and bearing materials that lower leakage and friction losses, and heat-recovery systems that capture compressor waste heat for facility heating. Combined, these technologies reduce electrical consumption and improve overall system ROI when tailored to actual duty profiles.

The next subsection lists practical technologies and typical benefits, and the following subsection explains how custom engineering applies these innovations to improve performance in specific installations.

What energy-saving technologies are available in 2026?

Key energy-saving options include VFDs for motor speed control and load-matching, heat recovery modules that repurpose thermal waste for building heating, advanced electronic controls with demand-side management and sequencing, and improved mechanical designs that reduce internal leakage and friction. Implementing smart monitoring enables predictive maintenance that prevents efficiency-robbing failures and optimizes run schedules. Quantified savings vary by site profile, but combining VFDs with optimized staging commonly delivers measurable reductions in electrical use versus fixed-speed systems. Adopting these technologies requires system-level analysis to ensure that control strategies and heat-recovery opportunities align with operational needs.

How do custom engineering solutions enhance compressor performance?

Custom engineering tailors staging, control logic, materials, and ancillary systems to site-specific duty cycles, environmental conditions, and air-quality demands, delivering higher efficiency and reliability than one-size-fits-all equipment. Examples include designing multi-stage compression with intercooling optimized for a particular PSI/SCFM profile, integrating VFDs and demand-based sequencing to minimize idle power, and specifying materials and coatings for marine environments to extend component life. These engineering choices reduce lifecycle cost by balancing CAPEX and OPEX—spending more initially for improved controls and heat recovery can pay back through lower energy bills and reduced maintenance. When efficiency and uptime are priorities, investing in custom solutions often yields the best long-term value.

LW Americas offers custom engineering services to integrate efficiency technologies and tailored control strategies into high pressure compressor systems for demanding sectors.

What factors influence the cost of high pressure air compressors?

Cost drivers for high pressure air compressors include compressor type (reciprocating vs rotary vs cascade), pressure rating and flow requirements, materials and corrosion protection, filtration and breathing-air certification, packaging and mobility, and the scope of aftermarket support and integration services. Higher PSI and tighter air-quality requirements increase complexity and material costs, while custom engineering, testing, and documentation also add to initial expenditure. Buyers must weigh upfront CAPEX versus projected OPEX savings from efficiency features and service agreements.

The table below maps common specifications and features to their relative cost impacts to help procurement teams prioritize trade-offs.

This breakdown shows that the most significant cost multipliers are pressure specification and air-quality requirements; buyers should match specification tightly to need rather than over-specifying capacity unnecessarily.

How do compressor type and specifications affect pricing?

Compressor type and specs scale price because higher pressure capability, larger continuous flow, and specialized materials each add mechanical complexity and testing requirements. For example, designing for extreme PSI requires additional stages, stronger cylinders, and more robust safety devices; similarly, specifying breathing-air filtration and validated testing procedures increases both component and documentation costs. Trade-offs between CAPEX and OPEX matter: spending more for advanced controls and heat recovery increases upfront cost but can lower operating expense over time. Buyers should request performance curves at the required PSI rather than generic flow ratings to understand true operational capacity and cost implications.

What should buyers consider when choosing manufacturers?

When choosing manufacturers, evaluate service and support capabilities, customization and engineering experience, spare parts availability, and proven delivery of application-specific systems like breathing-air or maritime packages. Ask prospective suppliers for case examples of similar installations, details on maintenance support and training, and information on warranty coverage and response times. An actionable buyer checklist includes required PSI/SCFM at operating point, air-quality standards, desired redundancy, space and environmental constraints, and expected duty cycle to include in RFPs. Prioritizing manufacturers that combine product quality with engineering support and responsive aftermarket service reduces integration risk and lifecycle cost.

For tailored quotes, project scoping, or to discuss custom-engineered high pressure compressor systems for diving, firefighting, maritime, medical, or industrial applications, contact LW Americas, which specializes in designing solutions that balance performance, safety, and reliability.

- Specify operational PSI and SCFM: Provide exact working pressure and required continuous or peak flow.

- Define air-quality requirements: State breathing-air or medical purity needs upfront.

- List environmental constraints: Note space, vibration limits, and corrosive conditions.

These steps help manufacturers produce accurate proposals and reduce costly revisions later in the procurement cycle.

For organizations requiring custom design, documented testing, and ongoing support, engaging a specialist supplier with experience across relevant sectors ensures the final system meets both performance and regulatory expectations.

For more information on high-pressure compressors, visit us at lwamericas.com.