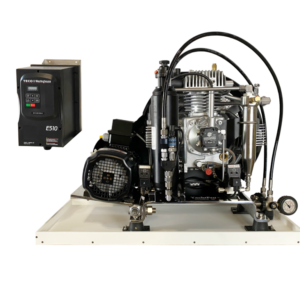

High-Pressure Air Compressor Features

High-pressure air compressors are essential for achieving optimal performance in air guns and paintball equipment. These compressors are designed to deliver consistent pressure levels, ensuring that users can fill their air tanks quickly and effectively.

Key features of high-pressure air compressors include adjustable pressure settings, efficient cooling systems, and portability options. For instance, the YachtPro™ series offers models with advanced cooling technology that minimizes heat buildup during operation, enhancing durability and reliability in the field.

Benefits of Using Compressed Air in Shooting Sports

Compressed air provides several advantages for shooting sports enthusiasts, particularly in terms of performance and convenience. Using compressed air instead of CO2 allows for more consistent shooting performance and greater accuracy.

Moreover, compressed air systems are environmentally friendly, as they eliminate the need for disposable CO2 canisters. This shift not only reduces waste but also ensures that shooters have a reliable source of air that can be refilled at their convenience, enhancing their overall experience during practice and competitions.

Choosing the Right Compressor for Your Needs

Selecting the appropriate compressor is crucial for users involved in shooting sports. Factors to consider include the type of air gun or paintball marker, the frequency of use, and the required pressure levels.

For example, competitive shooters may benefit from high-capacity models like the YachtPro™ 250, which can fill multiple tanks quickly, while recreational users might prefer more compact options that offer portability without sacrificing performance. Understanding these needs can help users make informed decisions that enhance their shooting experience.

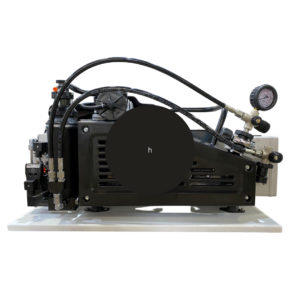

Maintenance Tips for High-Pressure Compressors

Proper maintenance of high-pressure compressors is vital for ensuring longevity and optimal performance. Regular checks on components such as filters, oil levels, and seals can prevent issues that may arise during use.

Additionally, users should follow manufacturer guidelines for periodic servicing and cleaning. For instance, replacing air filters every few months and inspecting hoses for wear can significantly reduce the risk of compressor failure and ensure that the equipment operates efficiently for years to come.

High-Pressure Air Compressor Features

High-pressure air compressors are essential for achieving optimal performance in air guns and paintball equipment. These compressors are designed to deliver consistent pressure levels, ensuring that users can fill their air tanks quickly and effectively.

Key features of high-pressure air compressors include adjustable pressure settings, efficient cooling systems, and portability options. For instance, the YachtPro™ series offers models with advanced cooling technology that minimizes heat buildup during operation, enhancing durability and reliability in the field.

Benefits of Using Compressed Air in Shooting Sports

Compressed air provides several advantages for shooting sports enthusiasts, particularly in terms of performance and convenience. Using compressed air instead of CO2 allows for more consistent shooting performance and greater accuracy.

Moreover, compressed air systems are environmentally friendly, as they eliminate the need for disposable CO2 canisters. This shift not only reduces waste but also ensures that shooters have a reliable source of air that can be refilled at their convenience, enhancing their overall experience during practice and competitions.

Choosing the Right Compressor for Your Needs

Selecting the appropriate compressor is crucial for users involved in shooting sports. Factors to consider include the type of air gun or paintball marker, the frequency of use, and the required pressure levels.

For example, competitive shooters may benefit from high-capacity models like the YachtPro™ 250, which can fill multiple tanks quickly, while recreational users might prefer more compact options that offer portability without sacrificing performance. Understanding these needs can help users make informed decisions that enhance their shooting experience.

Maintenance Tips for High-Pressure Compressors

Proper maintenance of high-pressure compressors is vital for ensuring longevity and optimal performance. Regular checks on components such as filters, oil levels, and seals can prevent issues that may arise during use.

Additionally, users should follow manufacturer guidelines for periodic servicing and cleaning. For instance, replacing air filters every few months and inspecting hoses for wear can significantly reduce the risk of compressor failure and ensure that the equipment operates efficiently for years to come.