Applications of Breathing Air Compressors

Breathing air compressors are essential in various industries, providing safe and reliable air for a multitude of applications. These compressors are utilized in medical settings for patient ventilation, in maritime operations for diving, and in industrial environments for safety and compliance with air quality standards.

For instance, in the medical field, breathing air compressors are used to supply oxygen for patients requiring respiratory support. In the maritime industry, they are critical for divers, ensuring that they have access to breathable air while underwater. Additionally, industries such as firefighting and hazardous material handling rely on these systems to maintain air quality and safety.

Benefits of Purification Systems

Purification systems are vital for ensuring that the air supplied by compressors is free from contaminants and safe for use. These systems remove impurities such as moisture, oil, and particulate matter, which can compromise the quality of breathing air and pose health risks.

For example, LW Americas' purification solutions are designed to meet the stringent requirements of medical and industrial applications, providing peace of mind to users. By implementing advanced filtration technologies, these systems enhance the performance of compressors, ensuring that the air delivered is of the highest quality and complies with industry standards.

Choosing the Right Compressor for Your Needs

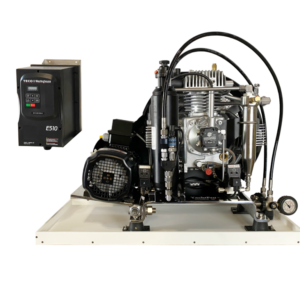

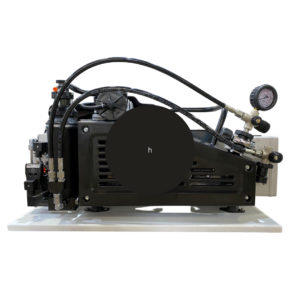

Selecting the appropriate breathing air compressor is crucial for meeting specific operational requirements. Factors such as the intended application, required pressure, and volume of air play a significant role in determining the best fit for your needs.

LW Americas offers a range of compressors tailored for various applications, from portable models for recreational diving to high-capacity systems for industrial use. By assessing your unique requirements, you can choose a compressor that not only meets your performance needs but also aligns with your budget and operational constraints.

Maintenance Tips for Breathing Air Systems

Regular maintenance of breathing air systems is essential to ensure their longevity and reliable performance. Implementing a routine maintenance schedule can help identify potential issues before they escalate, ensuring that the systems operate efficiently and safely.

Key maintenance practices include regularly checking and replacing filters, inspecting hoses and connections for wear, and ensuring that the compressor is properly lubricated. Additionally, conducting periodic air quality tests can help verify that the systems are delivering safe breathing air, which is critical for both safety and compliance in various industries.

Applications of Breathing Air Compressors

Breathing air compressors are essential in various industries, providing safe and reliable air for a multitude of applications. These compressors are utilized in medical settings for patient ventilation, in maritime operations for diving, and in industrial environments for safety and compliance with air quality standards.

For instance, in the medical field, breathing air compressors are used to supply oxygen for patients requiring respiratory support. In the maritime industry, they are critical for divers, ensuring that they have access to breathable air while underwater. Additionally, industries such as firefighting and hazardous material handling rely on these systems to maintain air quality and safety.

Benefits of Purification Systems

Purification systems are vital for ensuring that the air supplied by compressors is free from contaminants and safe for use. These systems remove impurities such as moisture, oil, and particulate matter, which can compromise the quality of breathing air and pose health risks.

For example, LW Americas' purification solutions are designed to meet the stringent requirements of medical and industrial applications, providing peace of mind to users. By implementing advanced filtration technologies, these systems enhance the performance of compressors, ensuring that the air delivered is of the highest quality and complies with industry standards.

Choosing the Right Compressor for Your Needs

Selecting the appropriate breathing air compressor is crucial for meeting specific operational requirements. Factors such as the intended application, required pressure, and volume of air play a significant role in determining the best fit for your needs.

LW Americas offers a range of compressors tailored for various applications, from portable models for recreational diving to high-capacity systems for industrial use. By assessing your unique requirements, you can choose a compressor that not only meets your performance needs but also aligns with your budget and operational constraints.

Maintenance Tips for Breathing Air Systems

Regular maintenance of breathing air systems is essential to ensure their longevity and reliable performance. Implementing a routine maintenance schedule can help identify potential issues before they escalate, ensuring that the systems operate efficiently and safely.

Key maintenance practices include regularly checking and replacing filters, inspecting hoses and connections for wear, and ensuring that the compressor is properly lubricated. Additionally, conducting periodic air quality tests can help verify that the systems are delivering safe breathing air, which is critical for both safety and compliance in various industries.