Nitrogen Applications in Various Industries

Nitrogen plays a crucial role across multiple industries, including medical, marine, and industrial sectors. In the medical field, nitrogen is utilized in hyperbaric oxygen therapy and radiology, providing essential support for patient care and diagnostic processes.

Similarly, in the marine industry, nitrogen is used for inert gas systems to prevent fire hazards and enhance safety on vessels. Industrial applications often involve nitrogen in processes like food packaging, metal production, and chemical manufacturing, highlighting its versatility and importance in maintaining quality and safety standards.

Benefits of Nitrogen Purification Systems

Nitrogen purification systems are essential for ensuring high-quality nitrogen gas is available for various applications. These systems remove impurities, moisture, and other contaminants, resulting in purified nitrogen that meets industry standards for safety and efficiency.

For instance, in the medical industry, purified nitrogen is critical for procedures requiring precise gas mixtures. Additionally, in industrial settings, using purified nitrogen can improve production processes, extend equipment life, and enhance product quality, making these systems a valuable investment for businesses.

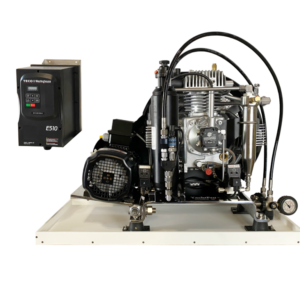

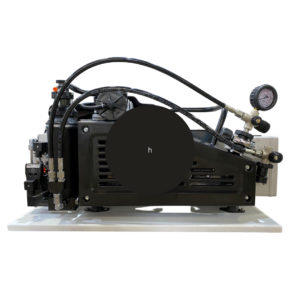

Choosing the Right Nitrogen Compressor

Selecting the appropriate nitrogen compressor is vital for optimizing performance and meeting specific operational needs. Factors to consider include the compressor's capacity, pressure levels, and intended application, as different industries may have unique requirements.

For example, a high-pressure compressor may be necessary for industrial applications, while a compact model might be ideal for marine use. Understanding these distinctions can help users make informed decisions, ensuring they choose a compressor that aligns with their operational goals and enhances productivity.

Maintenance Tips for Nitrogen Equipment

Regular maintenance of nitrogen equipment is essential to ensure optimal performance and longevity. This includes routine checks on compressors, purification systems, and storage tanks to identify any potential issues before they become significant problems.

Key maintenance practices involve monitoring pressure levels, replacing filters in purification systems, and inspecting storage tanks for leaks or corrosion. Implementing a proactive maintenance schedule can help prevent downtime, reduce repair costs, and ensure that nitrogen systems operate efficiently across all applications.