Overview of Car Jacks and Their Applications

Car jacks are essential tools for automotive professionals and enthusiasts, providing the necessary lift to perform repairs and maintenance. These devices come in various types, including hydraulic, scissor, and electric jacks, each designed to cater to different vehicle sizes and lifting requirements.

For instance, hydraulic jacks are favored in professional settings for their high lifting capacity and stability, while scissor jacks are more compact and suitable for emergency situations. Understanding the specific applications of each type can help users select the right tool for their needs, ensuring safety and efficiency during vehicle servicing.

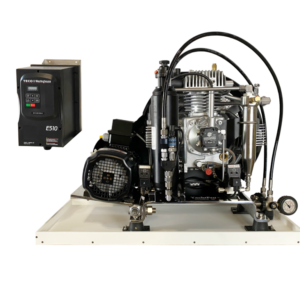

Choosing the Right High-Pressure Equipment

Selecting the appropriate high-pressure equipment is crucial for achieving optimal performance in marine and motorsports applications. Factors such as pressure requirements, compatibility with existing systems, and intended usage scenarios must be carefully considered to ensure the best fit.

For example, a racing team may require high-pressure compressors that provide quick refills and consistent performance during competitions, while a marine operation might prioritize durability and resistance to corrosion. Evaluating these criteria helps users make informed decisions that enhance their operational efficiency and safety.

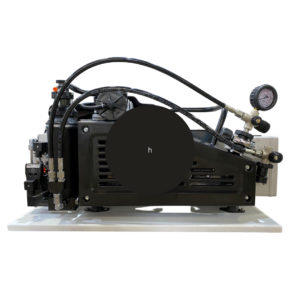

Maintenance Tips for High-Pressure Equipment

Regular maintenance of high-pressure equipment is vital to ensure longevity and reliable performance. Users should establish a routine inspection schedule to check for wear and tear, fluid levels, and any signs of malfunction.

For instance, lubricating moving parts and replacing worn seals can prevent costly breakdowns and extend the lifespan of compressors and jacks. Additionally, following manufacturer guidelines for maintenance can help users avoid common pitfalls and keep their equipment functioning at peak efficiency.

Innovations in High-Pressure Technology

The field of high-pressure technology is continuously evolving, with new innovations enhancing efficiency and safety. Recent advancements include the development of smart compressors that integrate IoT technology for real-time monitoring and performance analytics.

These innovations not only improve operational efficiency but also allow users to proactively address potential issues before they escalate. Staying informed about the latest trends and technologies can provide a competitive edge in industries reliant on high-pressure solutions.