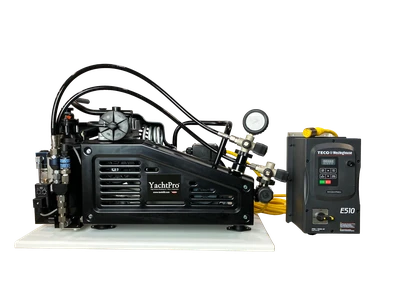

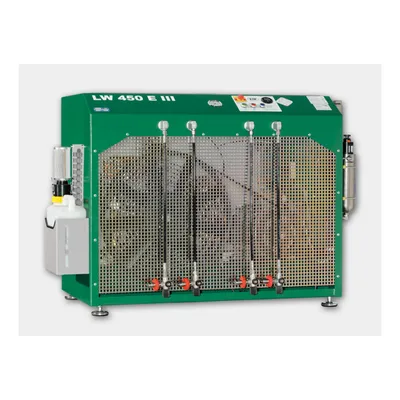

Advantages of Continuous-Duty Compressors

Continuous-duty compressors offer significant advantages over traditional models, particularly in high-demand environments. These compressors are designed to operate for extended periods without the need for cooling breaks, ensuring a steady supply of compressed air or gas, which is crucial for industries like diving and firefighting.

For example, the one-piece cast block design minimizes leak paths and enhances durability, while lower RPM operation reduces noise and vibration. This means that users can rely on these compressors for consistent performance, which is essential in critical applications where downtime can lead to safety risks or operational inefficiencies.

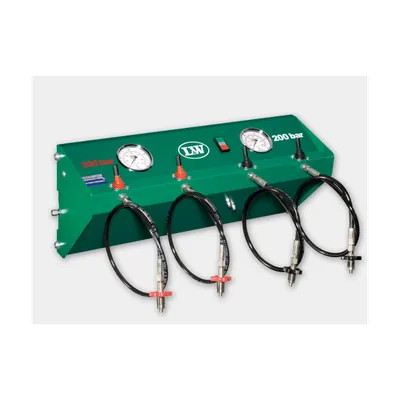

Maintenance Tips for High-Pressure Compressors

Regular maintenance is vital to ensure the longevity and efficiency of high-pressure compressors. Users should follow a routine maintenance schedule that includes checking oil levels, inspecting filters, and monitoring pressure gauges to prevent potential issues before they escalate.

Additionally, cleaning air intake filters and ensuring that cooling systems are functioning properly can significantly extend the life of the compressor. By adhering to these maintenance practices, operators can avoid costly repairs and ensure optimal performance in demanding environments.

Innovative Technologies in Compressor Design

The evolution of compressor technology has led to significant advancements that enhance performance and efficiency. Innovations such as variable speed drives and advanced cooling systems allow for better energy management and reduced operational costs.

For instance, the integration of smart technology in compressors enables real-time monitoring and diagnostics, allowing users to track performance metrics and receive alerts for any anomalies. This proactive approach to maintenance not only improves reliability but also maximizes productivity across various industrial applications.

Applications of High-Pressure Compressors in Medical Fields

High-pressure compressors play a crucial role in the medical field, particularly in supplying breathing air for patients and powering medical equipment. These compressors must meet stringent safety and quality standards to ensure that the air delivered is free from contaminants.

In hospitals and emergency medical services, reliable compressor systems are essential for operating ventilators and other life-support devices. The ability to provide a continuous supply of high-quality compressed air can significantly impact patient outcomes, making the choice of compressor technology a critical decision for healthcare providers.