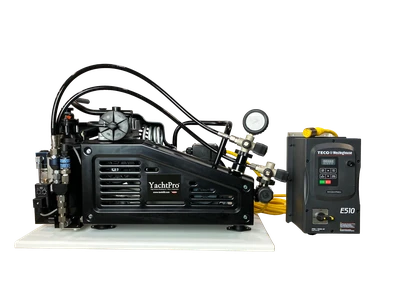

Benefits of Continuous-Duty Compressors

Continuous-duty compressors offer significant advantages for industries requiring consistent and reliable air supply. Unlike traditional compressors that need to cool down between uses, continuous-duty models can operate indefinitely, ensuring that operations remain uninterrupted and efficient.

This uninterrupted operation is particularly beneficial in high-demand environments, such as diving or firefighting, where every second counts. Additionally, these compressors typically feature advanced engineering designs, such as a one-piece cast block, which enhances durability and minimizes maintenance needs over time.

Maintenance Tips for High-Pressure Compressors

Regular maintenance is crucial for ensuring the longevity and performance of high-pressure compressors. Users should adhere to a schedule that includes routine inspections, oil changes, and filter replacements to keep the compressor running smoothly and efficiently.

Moreover, it's important to monitor the compressor's performance metrics, such as pressure levels and noise output, to identify potential issues early. Implementing a proactive maintenance plan not only extends the lifespan of the equipment but also enhances safety and reliability in critical applications.

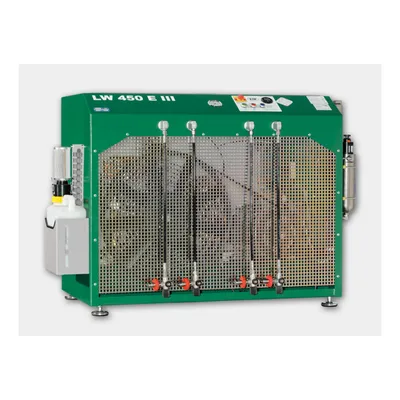

Comparative Analysis of Compressor Types

When selecting a compressor, understanding the differences between various types is essential. Continuous-duty compressors, for instance, are designed for high output and efficiency, while portable models may offer flexibility but lack the same level of performance under sustained use.

In applications like diving or medical use, where air quality and reliability are paramount, continuous-duty compressors stand out due to their robust construction and superior design. This comparison helps users make informed decisions based on their specific operational needs and constraints.

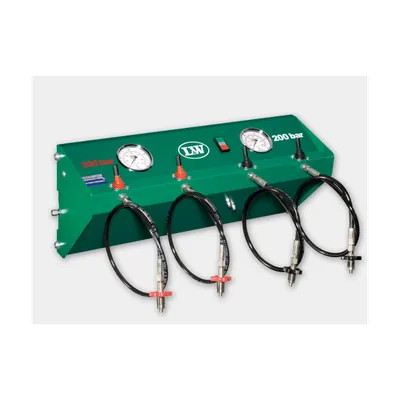

Innovations in Compressor Technology

The field of compressor technology is continually evolving, with innovations aimed at enhancing efficiency, reducing noise, and improving overall performance. Recent advancements include the integration of smart technology for real-time monitoring and diagnostics, allowing users to optimize their operations.

Additionally, developments in materials and design, such as the use of advanced alloys and streamlined configurations, contribute to the durability and efficiency of modern compressors. These innovations not only improve user experience but also align with sustainability goals by reducing energy consumption and emissions.