Choosing a High Pressure Air Compressor for Your Dive Shop: A Practical Decision Guide

Selecting a high pressure air compressor for a dive shop is a critical operational decision that impacts safety, efficiency, and profitability. This guide provides a structured approach to evaluating compressor systems, focusing on practical decision factors rather than just specifications. We’ll explore how to match equipment to your shop’s specific throughput, operational environment (fixed vs. mobile), and risk tolerance, emphasizing the importance of breathing-air quality, robust maintenance, and a clear understanding of total cost of ownership. Dive shop operators will learn to navigate choices related to compressor types, filtration design, air sampling logistics, and energy efficiency, ensuring a compliant and reliable air supply for scuba tank refills.

Choosing the Right Compressor System for Your Dive Shop

The ideal high pressure air compressor system for a dive shop delivers breathing air at the required pressure and flow for safe, repeated scuba cylinder refills. The best choice depends heavily on your shop’s daily fill volume, whether operations are fixed or mobile, and specific site constraints. Understanding the core compressor technology—high-pressure piston compressors—and how they are configured into systems (e.g., with cascade storage or as portable units) is key to making an informed decision.

Scenario-Based Selection: Matching Compressor Systems to Operational Needs

Consider your typical daily fill volume and operational model to guide your selection:

- Low Daily Fills (e.g., 5-10 tanks/day, occasional mobile use): A smaller, compact high-pressure piston compressor, potentially integrated into a portable skid, might suffice. Focus on ease of transport and basic filtration.

- Medium Daily Fills (e.g., 10-30 tanks/day, fixed location): A robust high-pressure piston compressor with a dedicated cascade fill system is often appropriate. Prioritize duty cycle, thermal management, and comprehensive multi-stage filtration.

- High Daily Fills (e.g., 30+ tanks/day, busy fixed location): A larger, continuous-duty high-pressure piston compressor, often paired with a substantial cascade storage system, is necessary. Focus on high throughput, advanced thermal management, and redundancy options.

- Mobile/Event-Based Fills: Portable high-pressure piston compressors (typically 3000-4500 psi) are essential. Evaluate their flow rate, self-contained power options, and integrated filtration for remote operations.

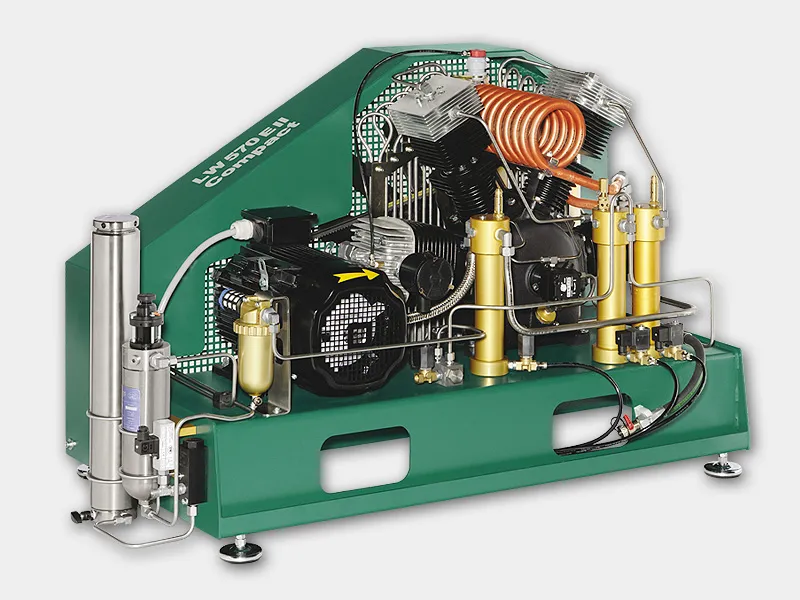

Understanding Compressor Types and Configurations

While the core technology for high-pressure breathing air is typically a multi-stage piston compressor, how it’s configured significantly impacts its application:

- High-Pressure Piston Compressors: These are the workhorses, compressing air in stages to achieve pressures up to 4500 psi or higher. Key considerations include:

Stage Count: More stages generally mean lower compression ratios per stage, leading to cooler operation and potentially longer component life.Thermal Management: Efficient intercoolers and aftercoolers are crucial for removing heat generated during compression, protecting components, and reducing moisture load on filtration.Duty Cycle: This defines how long a compressor can run continuously versus needing rest. Dive shop compressors often require high duty cycles, sometimes continuous, especially when paired with cascade systems. - Portable Compressor Systems: These are compact, self-contained high-pressure piston compressors designed for mobility.

Typical Pressure Rating: Commonly 3000-4500 psi, suitable for standard scuba cylinders.Flow / Use-case: Ideal for field fills, charters, and remote events where fixed installations are impractical. They typically have lower flow rates than larger fixed systems.Operational Trade-offs: While offering mobility, they may have limited continuous run times, require more frequent pauses between fills, and often have smaller, less robust filtration systems compared to fixed units, necessitating careful monitoring. - Cascade Fill/Storage Systems: These are not a compressor type but a configuration that pairs a compressor with multiple high-pressure storage cylinders.

Function: The compressor fills the storage cylinders, and then tanks are filled from the cascade bank, moving from highest to lowest pressure. This allows for rapid, successive fills without waiting for the compressor to build pressure for each tank.Benefits: Significantly increases effective fill rate during peak demand, reduces wear on the compressor by allowing it to run more continuously to fill the cascade bank rather than stop-start for each tank, and provides a buffer of air.Considerations: Requires additional footprint for storage cylinders and proper manifolding.

Key Operational Considerations: Duty Cycle and Throughput

Duty Cycle and Continuous-Duty Operation

A compressor’s duty cycle indicates the percentage of time it can operate within a given period. For dive shops, especially those with medium to high daily fills, understanding duty cycle is critical:

- Stop-Start Limitations: Frequent stop-start cycles can increase wear on motors, starters, and compressor components, leading to premature failure and higher maintenance costs.

- Thermal Management: Compressors generate significant heat. Continuous-duty units are designed with robust cooling systems (intercoolers, aftercoolers, larger fans) to dissipate this heat effectively, preventing overheating and thermal breakdown of lubricants or seals. Units not designed for continuous duty will overheat if pushed beyond their limits, compromising performance and longevity.

- Peak-Hour Impact: During busy periods, a compressor with an insufficient duty cycle will struggle to keep up, leading to slow fills, operator frustration, and potential equipment damage. A continuous-duty compressor, often paired with a cascade system, can maintain consistent output during peak demand.

Practical Throughput Calculations

To determine if a compressor system meets your fill rate needs, consider the following:

- Compressor Flow Rate (cfm / lpm): This is the volume of air the compressor can produce per minute. A higher flow rate means faster filling of both scuba tanks and cascade storage.

- Receiver Volume (for Cascade Systems): The total volume of your cascade storage cylinders directly impacts how many tanks you can fill rapidly before the compressor needs to replenish the bank. Larger cascade banks provide more buffer.

- Fills-Per-Hour Estimation:

Calculate the total volume of air needed per scuba tank fill (e.g., a 80 cu ft tank filled to 3000 psi).

Determine the compressor’s effective output volume per hour.

For cascade systems, factor in the initial volume available in the cascade bank and the compressor’s ability to replenish it while fills are ongoing.

A common approach is to size the compressor to replenish the cascade bank within a reasonable timeframe, allowing for continuous filling from the cascade.

Ensuring Breathing Air Quality and Compliance

Delivering safe breathing air is paramount for any dive shop. This requires adherence to specific standards, meticulous filtration design, and rigorous air sampling protocols.

Primary Standards: CGA G-7.1 vs. ISO 8573-1

- CGA G-7.1 (Commodity Specification for Air): This is the definitive breathing-air standard, particularly in North America, specifying acceptable contaminant concentrations (e.g., oil vapor, carbon monoxide, particulates, moisture) and sampling procedures for scuba applications. Adherence to CGA G-7.1 directly reduces the risk of contaminants harming divers.

- ISO 8573-1 (Compressed Air Purity Classification): It is crucial to understand that **ISO 8573-1 is NOT a breathing-air standard.** Instead, it is a compressed air purity classification system that defines purity classes for particulates, water, and oil. It provides a framework for specifying and verifying the performance of filtration stages. While not a breathing-air standard itself, ISO 8573-1 can be used as a supporting framework to specify filtration performance that helps achieve the breathing-air quality dictated by CGA G-7.1.

In practice, CGA G-7.1 dictates the required breathing-air quality, while ISO 8573-1 provides a technical language for selecting and verifying the filtration stages needed to achieve that quality.

Comprehensive Filtration System Design

A multi-stage filtration stack is essential to address various contamination paths and ensure breathing-air quality. Even “oil-free” compressor designs, which reduce lubricant carryover, still require full breathing-air filtration and testing to remove other contaminants.

Contamination Paths to Address:

- Intake Air Quality: Ambient air can contain pollutants, dust, pollen, and even exhaust fumes from nearby vehicles or generators.

- Moisture: Atmospheric air contains water vapor, which condenses into liquid water during compression.

- Thermal Breakdown: High temperatures during compression can cause compressor lubricants to break down into harmful vapors (e.g., carbon monoxide, hydrocarbons).

- Particulates: Wear particles from compressor components, rust from piping, or dust from intake.

- Upstream Engine Exhaust: If the compressor is powered by an internal combustion engine, exhaust gases can be drawn into the intake if not properly managed.

Multi-Stage Filtration Components:

A typical breathing-air filtration system includes:

- Pre-filters: Remove large particulates and bulk liquid water.

- Coalescing Filters: Remove fine oil aerosols and remaining liquid water.

- Activated Carbon Beds: Adsorb oil vapors, hydrocarbons, and odors.

- Desiccant Dryers (optional but recommended): Further reduce moisture content, especially in humid environments.

- Final Particulate Filters: Capture any remaining fine particles before the air enters the cylinder.

Sizing Filtration for Flow, Humidity, and Runtime:

- Flow Rate: Filter elements must be sized appropriately for the compressor’s maximum flow rate (cfm / lpm). Undersized filters lead to excessive pressure drop, reduced service life, and risk of contaminant breakthrough.

- Ambient Humidity: In humid climates, more robust moisture removal (e.g., larger coalescers, desiccant dryers) is critical to prevent water from reaching later filtration stages and compromising their effectiveness.

- Runtime Expectations: Filters have a finite life based on the volume of air processed and contaminant load. Systems with higher runtime expectations require larger filter elements or more frequent replacement schedules.

- Contamination Risk: If the intake air quality is consistently poor, or if there’s a higher risk of lubricant carryover, more aggressive or redundant filtration stages may be necessary.

Air Sampling Logistics

Regular air sampling is the only way to verify that your filtration system is performing as required and that the breathing air meets standards like CGA G-7.1.

- Sample Port Placement and Accessibility: When selecting a compressor system, ensure it has easily accessible, properly located sample ports. These ports should be downstream of all filtration stages and before the fill whip connection to ensure the sample represents the air entering the scuba tank. Poorly placed or inaccessible ports can complicate sampling and lead to non-compliance.

- Conditional Sampling Intervals: The frequency of air sampling is not fixed but depends on several factors:

Jurisdictional Requirements: Local regulations or national standards may mandate specific intervals (e.g., monthly, quarterly).Insurer Requirements: Your insurance provider may have specific sampling frequency requirements to maintain coverage.Usage-Dependent: High-volume shops or those operating in challenging environments (e.g., high humidity, dusty conditions) may need more frequent sampling.Risk Profile: Any changes to the compressor system, maintenance practices, or a history of borderline test results should trigger more frequent sampling. - Documentation Requirements: Maintain meticulous records of all air samples, including dates, results, and comparison to applicable standards. This documentation is crucial for demonstrating compliance to auditors and insurers.

Maintenance Discipline and Preventing Operational Failure

An effective maintenance program is not just about changing parts; it’s about preventing common failure modes that compromise breathing-air quality, reduce uptime, and increase total cost of ownership. Understanding how neglect manifests operationally is key to proactive maintenance.

Understanding Failure Modes and Operational Impact

- Filter Neglect:Manifestation: Overdue filter elements become saturated, leading to increased pressure drop, reduced flow, and ultimately, contaminant breakthrough. This can result in oil aerosols, particulates, or hydrocarbons entering scuba tanks, directly compromising diver safety.Operational Impact: Slow fills, reduced compressor efficiency, and potential for failed air quality tests, leading to costly remediation or even operational shutdown.

- Moisture Accumulation:Manifestation: Inadequate draining of moisture separators or coalescing filters allows liquid water to carry over into subsequent filtration stages, reducing their effectiveness and potentially causing corrosion within the compressor or storage cylinders.Operational Impact: Increased wear on compressor components, compromised air quality (e.g., high moisture content in breathing air), and potential for rust or corrosion in scuba tanks.

- Cooling System Inefficiency:Manifestation: Clogged intercoolers/aftercoolers, dirty cooling fins, or malfunctioning fans lead to elevated operating temperatures. This can cause thermal breakdown of compressor lubricants, increased moisture load on filters, and excessive wear on seals and components.Operational Impact: Reduced compressor lifespan, increased risk of carbon monoxide formation (from lubricant breakdown), higher energy consumption, and potential for sudden compressor shutdown due to overheating.

Scheduled Maintenance Program

A structured maintenance program combines daily checks with periodic replacements and annual performance testing:

- Daily: Visual inspection for leaks, abnormal noises or vibrations, moisture drain from receivers and separators, and basic pressure checks.

- Monthly/Quarterly (conditional on usage, jurisdiction, insurer): Filter element checks, carbon bed monitoring (e.g., for breakthrough indicators), and quick tests for oil aerosol or CO (if equipped with sensors).

- Semi-annual/Annual: Full service including replacement of all filter elements, oil change, valve inspection, intercooler/aftercooler cleaning, belt tension checks, and comprehensive performance testing against flow and pressure specifications.

This structured approach minimizes contamination risk and creates a defensible record of preventive care for auditors and insurers.

Documentation for Compliance and Audit Trails

Every maintenance task, filter change, oil change, and air sample result must be meticulously logged. This documentation serves multiple purposes:

- Compliance: Provides evidence to regulatory bodies and insurers that the system is maintained according to standards.

- Troubleshooting: Helps identify patterns or recurring issues, aiding in faster diagnosis and repair.

- Asset Management: Tracks component lifespan and helps predict future maintenance needs and costs.

Total Cost of Ownership and Procurement Considerations

The true cost of a compressor system extends far beyond its initial purchase price. Total Cost of Ownership (TCO) includes energy consumption, maintenance, and the financial impact of downtime. Strategic procurement also involves asking the right questions of potential vendors.

Beyond Purchase Price: Energy, Maintenance, Downtime

To evaluate TCO, follow these practical steps:

- Estimate Energy Use: Multiply expected annual operating hours by the system’s kW draw to calculate yearly kWh and electrical cost. Consider the impact of variable speed drives (VFDs) if applicable, which can significantly reduce energy consumption during periods of lower demand.

- Quantify Maintenance: Add annualized costs for filter elements, compressor oil, and labor hours for scheduled servicing. Factor in the lifespan of major components.

- Value Uptime: Estimate the revenue lost per hour of downtime (e.g., inability to fill tanks, lost retail sales) and include the likely downtime from each design option. Prioritize features that enhance reliability and ease of service.

Energy Efficiency and Electrical Infrastructure

Energy consumption is a major component of TCO. Consider these factors:

- Single-Phase vs. Three-Phase Power: Larger, more powerful compressors typically require three-phase electrical service, which may not be available or may require costly upgrades in some locations. Smaller portable units often run on single-phase.

- Heat Rejection and Ventilation: Compressors generate substantial heat. Adequate ventilation is crucial to prevent the compressor room from overheating, which can reduce compressor efficiency, shorten component life, and increase air conditioning costs for the facility. Consider the heat load the compressor will add to your shop’s environment.

- Electrical Limitations: Ensure your existing electrical panel and wiring can safely support the compressor’s starting and running amperage.

- Variable Speed Drives (VFDs): VFDs adjust motor speed to match demand, significantly reducing energy consumption during periods of partial load compared to fixed-speed compressors that run at full power or cycle on/off.

Vendor Evaluation and Key Questions

Engaging with potential vendors requires asking specific questions to ensure long-term support and compliance:

- Service Access and Parts Availability: How easy is it to access components for routine service? Are common wear parts (e.g., valves, seals) readily available, and what is the typical lead time?

- Filtration Consumables and Support: What is the cost and availability of replacement filter elements and compressor oil? Does the vendor offer bulk discounts or service contracts that include consumables?

- Sampling Support and Documentation: Does the vendor provide guidance on air sampling procedures or offer sampling kits? What documentation (e.g., maintenance logs, test certificates) is provided with the system?

- Technical Support and Training: What level of technical support is available? Is operator training provided for maintenance and troubleshooting?

- Warranty: Understand the warranty terms for the compressor and its components.

For dive shops ready to move from specification to procurement, prepare a short brief with desired fills per day, preferred maximum footprint, and required purity class to get precise recommendations and comparative lifecycle estimates. Engaging a specialist early in the process reduces rework, ensures sampling ports and maintenance access are included, and shortens time to compliant operation. To discuss your situation specifically with an experienced member of our team in South Florida, contact LW Americas here.