How Oil Separators Extend Air Compressor Life: Benefits & Maintenance

In oil-injected compressed air systems, efficient oil separation extends equipment life by removing oil mist and droplets, which prevents internal corrosion and wear. For oil-free compressors, different filtration stages are employed to ensure purity. Both approaches maintain high-quality, low-oil air for critical applications. This article outlines how oil separators function, the science behind oil removal, the key advantages they deliver, available separator types, LW Americas’ tailored solutions for high-pressure compressors, and best practices for maintenance and environmental compliance. You will learn:

- What an oil separator is and its essential role in air compressors.

- The principles of coalescence, multi-stage filtration, and condensate management.

- Tangible benefits like reduced wear, energy savings, and cost reduction.

- How to select, install, and upkeep separators for maximum longevity.

- LW Americas’ integrated technologies that enhance high-pressure compressor performance.

What Is an Air Compressor Oil Separator and Why Is It Essential?

An air compressor oil separator is a filtration device that captures oil aerosols and mist from compressed air, ensuring clean output and protecting downstream equipment from contamination. By separating oil from air, it maintains compressor lubrication balance and extends component life, which is critical for diving, medical, and industrial systems. Understanding this core purification stage sets the foundation for exploring separation mechanisms and long-term reliability.

What Is the Primary Function of an Oil Separator in Air Compressors?

An oil separator’s primary function is to remove entrained oil droplets from the compressed airflow, with premium coalescing units capable of producing oil content as low as 1 ppm. It achieves this by redirecting the air through coalescing media that aggregates microscopic oil particles into larger droplets for gravity drainage. This process safeguards valves, piping, and end-use equipment from oil fouling and preserves compressor efficiency.

How Do Oil Separators Improve Compressed Air Quality?

Oil separators improve compressed air quality by extracting oil mist that causes product contamination, microbial growth, and pneumatic tool failure. Clean air reduces deposit buildup in downstream filters and actuators, which prevents pressure fluctuations and preserves consistent airflow. Enhanced purity supports compliance with ISO 8573-1 air quality classes and protects processes in food, medical, and breathing air applications.

Introduction to ISO 8573-1

ISO 8573-1 is a crucial international standard that defines air quality classes for compressed air systems, categorizing air based on levels of solid particles, water, and total oil. It specifies maximum allowable concentrations for these contaminants, with Class 0 representing the most stringent purity level required for sensitive applications.

This white paper provides foundational information on ISO 8573-1, which the article references for improving compressed air quality and ensuring compliance with purity standards.

What Are the Key Components of an Air Compressor Oil Separator?

Oil separators consist of several critical components that work in tandem to purify compressed air:

- Coalescing Filter Element: A multilayer micro-glass fiber cartridge that merges oil droplets into larger aggregates.

- Separator Housing: A pressure-rated vessel that guides airflow through filtration media and collects separated oil.

- Scavenge or Drain Valve: An automatic or manual valve that expels accumulated oil condensate from the housing.

- Inlet and Outlet Ports: Precision fittings that control flow velocity for optimal separation.

These parts together ensure efficient oil removal and reliable condensate management, laying the groundwork for ongoing compressor protection.

How Does Oil Separation Prevent Wear and Tear in Compressors?

Oil separation prevents wear and tear by reducing abrasive oil particles that erode cylinder walls, pistons, and bearings. By delivering clean air back into the compressor cycle, the separator minimizes sludge formation and corrosion. This continuous purification lowers friction, stabilizes operating temperatures, and preserves mechanical tolerances, directly extending compressor service intervals and overall lifespan.

How Do Air Compressor Oil Separators Work? Understanding the Science Behind Oil Removal

Oil separators rely on physical principles to capture and eliminate oil from compressed air. The following sections break down the core scientific mechanisms that enable high-purity airflow in demanding applications.

What Is the Coalescence Principle in Oil Separation?

Coalescence merges microscopic oil aerosols into larger droplets through surface attraction within oleophilic media. As oil-laden air passes through micro-glass fiber layers, individual oil particles adhere to fibers and coalesce into droplets that grow heavy enough to fall out of the airflow. This principle transforms dispersed oil into recoverable liquid, ensuring air purity and enabling efficient condensate drainage.

Coalescing oil separator for compressors

This research investigates the coalescence mechanism for oil droplet separation in compressors, utilizing flow visualization and analytical models. The study reveals important flow details such as oil droplet collision and coalescence, and provides quantitative guidelines for the design and operation of coalescing oil separators.

This research directly supports the article’s explanation of the coalescence principle and the scientific mechanisms behind oil removal in air compressors.

How Does Multi-Stage Filtration Enhance Oil Removal Efficiency?

Multi-stage filtration combines coarse mechanical separation with fine coalescing to maximize oil extraction:

- Primary Separator: Eliminates large oil droplets via centrifugal forces.

- Secondary Coalescer: Uses micro-fiber cartridges to trap sub-micron aerosols.

- Polishing Filter: Provides final removal of residual oil particles down to 1 ppm.

This staged approach balances pressure drop with high removal rates, offering consistent performance in high-pressure and industrial environments.

What Role Does Oil-Water Separation Play in Condensate Management?

Oil-water separators treat compressor condensate by separating hydrocarbons from moisture before disposal. After coalescing removes oil from air, condensed water collects in drains and carries trace oil. An oil-water separator channels this mixture through hydrophobic membranes or adsorption media, producing water suitable for sewage discharge and concentrated oil for recycling. Effective condensate treatment prevents environmental fines and safeguards drainage systems.

What Are the Benefits of Using Oil Separators to Extend Air Compressor Lifespan?

Implementing an efficient oil separator yields measurable advantages in equipment reliability, energy consumption, and operational costs, driving value across industries.

How Do Oil Separators Reduce Internal Component Wear and Tear?

Oil separators reduce wear by filtering oil droplets that would otherwise deposit inside cylinders and bearings. Cleaner internal surfaces experience less friction and corrosion, which decreases mechanical stress and extends component life. Customers report up to 30 percent longer overhaul intervals when oil separators maintain sub-ppm oil levels.

In What Ways Do Oil Separators Boost Energy Efficiency in Compressed Air Systems?

Efficient oil removal minimizes pressure drop across the compressor loop, reducing the work required to maintain set pressure. Lower differential pressure translates directly into energy savings—often between 5 and 15 percent in continuous-run systems, though actual savings can vary based on system configuration and duty cycle. By maintaining optimal airflow, separators also decrease downtime for corrective filtration, supporting stable power consumption.

How Do Oil Separators Lower Maintenance Costs and Downtime?

Oil separators decrease maintenance costs by preventing oil carryover that clogs downstream filters and piping. Fewer blockages mean extended service intervals for post-filters and valves, cutting expenses on replacement parts and labor. Reduced unplanned downtime improves production uptime and lowers lifecycle costs, with a return on investment often observed within 12 to 18 months, though actual savings and ROI periods can vary significantly based on specific operating conditions and system configurations.

How Do Oil Separators Ensure Compliance with Environmental Regulations?

Oil separators support environmental compliance by capturing oil in condensate and preventing hydrocarbon discharge. Treating condensate in oil-water separators ensures effluent meets EPA Title 40 CFR Part 279 standards for oily water, avoiding fines and protecting ecosystems. Reliable condensate management demonstrates corporate responsibility and meets stringent air quality regulations.

What Types of Air Compressor Oil Separators Are Available and How to Choose the Right One?

Selecting the appropriate separator depends on compressor type, operating pressure, and air quality requirements. The following table compares core separator technologies.

What Are the Differences Between Coalescing, Centrifugal, and Adsorption Oil Separators?

Coalescing filters rely on fiber media that attracts and merges oil particles, achieving sub-micron removal. Centrifugal separators spin air to fling heavier droplets outward, simplifying maintenance but yielding moderate purity. Adsorption separators trap dissolved hydrocarbons on activated carbon, providing the highest purity for critical gas applications but requiring periodic media replacement.

How Do High-Pressure Air Compressor Oil Separators Differ from Standard Models?

High-pressure separators feature reinforced housings rated for pressures up to 450 bar and optimized media layers to withstand elevated airflow velocities. They incorporate robust drain valves and scavenge systems to handle greater condensate volumes while maintaining minimal pressure drop. Engineering precision ensures reliable performance under extreme conditions common in diving and industrial gas compression.

When Should You Opt for Integrated Oil-Water Separators Versus External Units?

Integrated oil-water separators are installed within the compressor package, offering compact footprint and synchronized maintenance intervals. External units provide flexibility for retrofits and can be scaled independently to match condensate flow. Choose integrated solutions for new high-pressure systems to streamline installation, or select external separators when upgrading existing compressors without enclosure modifications.

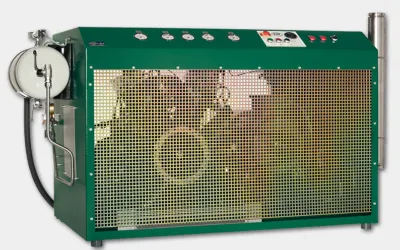

How Does LW Americas Provide Advanced Oil Separation Solutions for High-Pressure Compressors?

LW Americas leverages over 50 years of expertise and partnership with L&W Compressors to deliver integrated oil separation tailored to demanding sectors. Their solutions combine German engineering precision with custom options for specialized requirements.

What Are the Features of LW Americas’ Integrated L&W Oil Separator Technology?

LW Americas’ integrated separators feature multilayer micro-glass coalescers, high-flow scavenge lines, and automatic condensate drains designed for continuous high-pressure operation. These separators remove oil mist to below 1 ppm while maintaining minimal pressure drop, ensuring reliable breathing air purity for diving and medical applications. These systems are engineered to meet stringent air quality standards, typically achieving ISO 8573-1 Class 1 or better for total oil content, ensuring suitability for even the most sensitive applications. The compact design fits seamlessly into L&W compressor skids for streamlined maintenance.

How Do LW Americas’ Custom Solutions Address Industry-Specific Oil Separation Challenges?

For firefighting and maritime sectors, LW Americas offers corrosion-resistant housings and quick-change filter cartridges to minimize service downtime. In industrial gas and sports diving applications, they provide specialized adsorption modules to meet ultra-low oil specifications. Tailored OEM support ensures each system aligns with client requirements, from condensate treatment to remote monitoring capabilities.

How Should You Maintain and Troubleshoot Your Air Compressor Oil Separator for Maximum Longevity?

Regular inspection and timely service of oil separators prevent performance degradation and preserve compressor life. The following list highlights common signs and recommended maintenance steps.

What Are the Signs That an Oil Separator Needs Replacement or Service?

Typical indicators of separator wear include:

- Increased oil carryover in downstream filters or separator bowls.

- Rising differential pressure across the separator housing.

- Elevated outlet air temperature, suggesting clogged media.

- Visible oil in condensate drains, implying media saturation.

Recognizing these signs early allows proactive service and prevents costly compressor damage.

What Are the Recommended Maintenance Practices and Intervals for Oil Separators?

Best practices for separator upkeep include:

- Monthly Visual Inspections of housing seals and drain valves.

- Quarterly Filter Element Replacement or per manufacturer’s differential pressure threshold.

- Annual Housing Integrity Tests to verify pressure-rating compliance.

- Documented Service Logs to track performance metrics and schedule upgrades.

Consistent maintenance ensures separators operate at peak efficiency and extend compressor overhaul intervals.

How Can You Troubleshoot Common Oil Separator Failures?

When separator efficiency drops, apply these troubleshooting steps:

- Check Drain Valve Operation to confirm condensate removal.

- Measure Inlet vs. Outlet Pressure to diagnose media blockage.

- Inspect Filter Media for Saturation or physical damage.

- Verify Correct Filter Orientation and proper housing assembly.

Systematic troubleshooting restores separator performance and prevents unexpected compressor downtime.

What Is the Environmental Impact of Oil Separators and How Do They Support Regulatory Compliance?

Oil separators play a dual role: protecting equipment and ensuring responsible wastewater management. Proper condensate treatment upholds environmental standards and corporate sustainability goals.

How Do Oil-Water Separators Treat Oily Condensate for Safe Disposal?

Oil-water separators direct condensate through coalescing plates or oleophilic membranes that partition oil from water. The treated water drains into authorized sewage systems, while collected oil is stored for recycling or safe disposal. This separation process prevents groundwater contamination and meets municipal discharge requirements.

What Are the Key Environmental Regulations Affecting Oil Separator Use?

Oil separator operations must comply with:

- EPA Title 40 CFR Part 279, governing used oil processing and disposal.

- ISO 8573-1, specifying compressed air purity classes for oil content.

- Local wastewater discharge permits, which set acceptable hydrocarbon thresholds.

40 CFR Part 279 – Standards for the Management of Used Oil

The Code of Federal Regulations, Title 40, Part 279, establishes comprehensive standards for the management of used oil, including its generation, collection, processing, and disposal. It prohibits the unlawful discharge of oil-mixed water into sewer systems, emphasizing the legal and environmental consequences of non-compliance.

This regulation directly supports the article’s discussion on environmental compliance, the safe disposal of oily condensate, and the prevention of environmental fines through proper oil separation.

How Does Proper Oil Separation Prevent Environmental Fines and Protect Ecosystems?

By capturing oil before disposal, separators keep hydrocarbons out of waterways and soil, preventing aquatic toxicity and soil degradation. Meeting regulatory oil-in-water limits averts fines and reputational damage. Effective condensate management contributes to cleaner operations and supports corporate sustainability objectives.

Preserving compressor performance through oil separation not only extends equipment life but also safeguards the environment and ensures regulatory compliance—delivering peace of mind and long-term value.

Effective oil separation establishes a strong foundation for reliable, energy-efficient compressed air systems that support critical industrial, medical, and recreational operations. Contact LW Americas for customized high-pressure compressor packages featuring integrated separators designed to deliver superior air purity, reduced maintenance, and compliance with the strictest environmental regulations. Experienced engineers stand ready to optimize your system for maximum longevity and performance.

Frequently Asked Questions

What maintenance practices are essential for ensuring the longevity of oil separators?

To maintain oil separators effectively, regular inspections and timely service are crucial. Monthly visual checks should be conducted to assess housing seals and drain valves. Quarterly, filter elements should be replaced based on the manufacturer’s differential pressure guidelines. Annual integrity tests of the housing ensure compliance with pressure ratings. Keeping documented service logs helps track performance metrics and schedule necessary upgrades, ensuring that the separator operates at peak efficiency and extends the overall lifespan of the compressor system.

How can oil separators impact energy efficiency in compressed air systems?

Oil separators significantly enhance energy efficiency by minimizing pressure drops within the compressor loop. When oil is effectively removed, the compressor requires less energy to maintain the desired pressure levels. This reduction in differential pressure can lead to energy savings of 5 to 15 percent in continuous-run systems, though actual savings can vary based on system configuration and duty cycle. By ensuring optimal airflow and reducing the need for corrective filtration, oil separators contribute to lower operational costs and improved overall system performance.

What are the environmental benefits of using oil separators in compressed air systems?

Oil separators play a vital role in environmental protection by preventing oil contamination in wastewater. They treat condensate by separating oil from water, allowing for safe disposal or recycling of the oil and ensuring that treated water meets regulatory standards. This process helps avoid fines for non-compliance with environmental regulations and protects ecosystems from harmful hydrocarbons. By implementing effective oil separation, companies can demonstrate corporate responsibility and commitment to sustainability.

How do different types of oil separators compare in terms of efficiency and application?

Different types of oil separators, such as coalescing, centrifugal, and adsorption separators, vary in efficiency and application suitability. Coalescing filters achieve high oil removal rates (90-98%) and are ideal for industrial and medical applications. Centrifugal separators offer moderate purity (80%) with low maintenance needs, suitable for coarse droplet removal. Adsorption separators provide the highest purity (95-99%) for critical gas applications but require regular media replacement. Choosing the right type depends on specific operational needs and desired air quality standards.

What are the signs that an oil separator may need servicing or replacement?

Indicators that an oil separator requires servicing or replacement include increased oil carryover in downstream filters, rising differential pressure across the separator, elevated outlet air temperatures, and visible oil in condensate drains. These signs suggest that the separator media may be clogged or saturated, which can lead to decreased performance and potential damage to the compressor. Early recognition of these symptoms allows for proactive maintenance, preventing costly repairs and ensuring optimal operation.

What role does oil-water separation play in managing compressor condensate?

Oil-water separation is crucial for managing compressor condensate by effectively separating hydrocarbons from moisture before disposal. After oil is removed from the compressed air, the condensate, which may still contain trace oil, is treated through oil-water separators. These devices utilize hydrophobic membranes or coalescing plates to ensure that the water is safe for discharge into sewage systems while collecting oil for recycling. This process not only meets environmental regulations but also protects drainage systems from contamination.

How do integrated oil-water separators differ from external units in compressor systems?

Integrated oil-water separators are built into the compressor package, offering a compact design and synchronized maintenance intervals, which can streamline operations. They are ideal for new high-pressure systems where space is limited. In contrast, external units provide flexibility for retrofitting existing systems and can be scaled independently to match varying condensate flows. Choosing between integrated and external separators depends on the specific installation requirements and whether modifications to existing compressor setups are feasible.

Conclusion

Implementing oil separators significantly enhances the lifespan and efficiency of air compressors by ensuring clean, low-oil air, which reduces wear and maintenance costs. These systems not only support compliance with environmental regulations but also contribute to energy savings and operational reliability. By choosing the right oil separator, you can optimize your compressed air system for peak performance and sustainability. Explore LW Americas’ tailored solutions today to elevate your compressor’s efficiency and longevity.