High-Pressure Air Compressor: Features, Specs & Applications

Delivering clean, pressurized air above 70 bar is critical for diving operations, firefighting support, industrial processes, and medical applications. Understanding high pressure air compressor features streamlines system selection, ensures safety compliance, and optimizes operational efficiency. This guide breaks down core components, advanced purification methods, essential safety controls, performance metrics, niche application requirements, buyer decision criteria, and maintenance best practices. By exploring each feature in depth, businesses gain the clarity needed to match compressor capabilities to their unique demands and leverage LW Americas’ expertise in custom high-pressure solutions.

What Are the Core Components of a High Pressure Air Compressor?

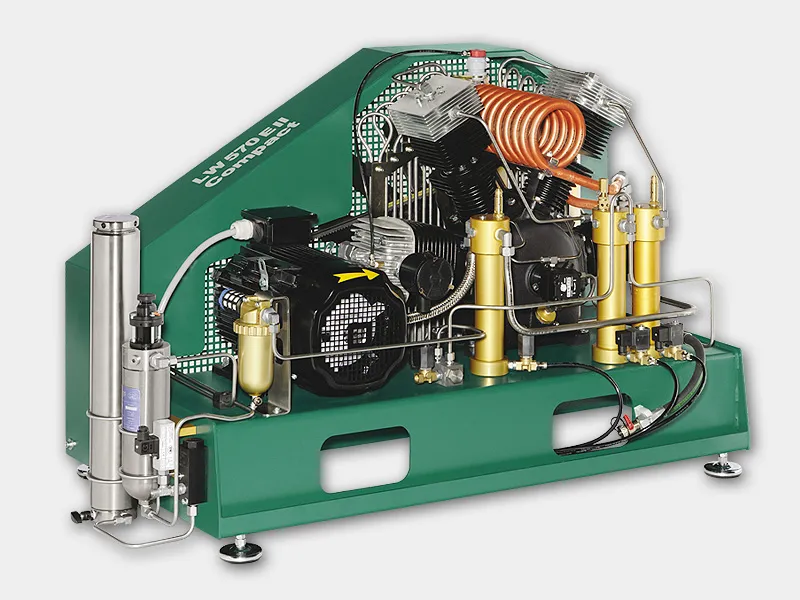

A high pressure air compressor integrates mechanical, pneumatic, and control elements to raise incoming atmospheric air to specified pressures. Core components include the compressor block and cylinders for staged compression, a powertrain of motor and drive system to generate torque, and manifold assemblies that direct airflow through intercoolers and purification modules. These elements work in concert to convert electrical or diesel energy into reliable, high-pressure delivery—for example, a 3-stage piston block elevates air to 330 bar, while a 4-stage compressor can exceed 420-bar for industrial applications and cascade filling of SCUBA tanks.

How Do Piston and Rotary Screw Compressors Differ in High Pressure Applications?

Piston compressors use reciprocating pistons within cylinders to achieve multi-stage compression, offering peak pressures that exceed 500 bar. Rotary screw compressors rely on intermeshing helical rotors to deliver a continuous flow of compressed air at moderate high pressures (up to 200 bar).

- Piston units excel in high peak-pressure scenarios but require more maintenance due to dynamic seals.

- Rotary screw variants deliver smoother pressure curves and lower vibration but typically cap at lower maximum pressures.

Each design’s mechanical configuration determines efficiency, maintenance cycle, and footprint, guiding system choice based on continuous vs. peak-demand profiles.

Piston vs Screw Compressor: Factors to consider

This article provides a detailed comparison of piston and rotary screw compressors, highlighting their advantages and disadvantages in terms of cost-effectiveness, pressure ratios, maintenance, efficiency, noise levels, and suitability for continuous operation. It notes that rotary screw compressors are generally more energy-efficient, delivering more air per unit of input energy, while piston compressors excel in high-pressure applications and intermittent use.

Atlas Copco, 2023

This research directly supports the article’s section on the differences between piston and rotary screw compressors in high-pressure applications, covering efficiency, maintenance, and operational profiles.

What Roles Do Compressor Blocks and Cylinders Play in Pressure Generation?

Compressor blocks and cylinders form the heart of staged air compression by progressively reducing volume and boosting pressure through sequential chambers. Key aspects include:

- Stage Count → Number of cylinders → Higher pressure ratio per stage

- Cylinder Material → Steel or aluminum alloy → Enhanced wear resistance

- Intercooler Integration → Heat exchanger placement → Lowers discharge temperature

These coordinated elements amplify air pressure while managing thermal loads, setting the stage for purification and distribution modules.

Which Motor and Drive Systems Power High Pressure Compressors?

Electric and diesel motors, often paired with variable frequency drives (VFDs), supply the torque required for high pressure compression. Typical configurations include:

- TEFC Electric Motor → Direct drive → Precise speed control

- Diesel Engine → Gearbox coupling → Portable operation

- VFD Controller → Modulates torque → Optimizes energy consumption

Selecting the appropriate powertrain ensures consistent pressure delivery, energy efficiency, and compatibility with site power availability.

How Does Advanced Air Purification Enhance Breathing Air Compressor Specifications?

Advanced air purification removes particulates, moisture, hydrocarbons, and CO contaminants to meet stringent breathing air standards. By integrating multi-stage filters, activated carbon beds, hopcalite, moisture separators, and air dryers, compressors produce OSHA grade E SCUBA air, medical-grade or SCBA-compliant air. For instance, firefighting units incorporate high-efficiency adsorbents to safeguard respiratory protection under NFPA guidelines.

What Is Multi-Stage Filtration and Why Is It Important?

Multi-stage filtration sequentially eliminates large particles, fine contaminants, oil vapors, and odors to achieve breathing air purity. Below is a breakdown of each stage’s function and efficiency:

Sequential filtration safeguards downstream systems and extends component life while ensuring compliance with ISO 8573-1, OSHA, and NFPA 1989 requirements.

How Do Activated Carbon and Hopcalite Filters Improve Air Quality for Breathing Applications?

Activated carbon filters adsorb volatile organic compounds and residual oil vapors that escape coalescing stages, enhancing taste and odor removal. Benefits include:

- Hydrocarbon Capture improves respiratory comfort.

- Extended Bed Life reduces replacement frequency.

- Low Pressure Drop maintains system efficiency.

Adsorption processes complement mechanical separation to deliver odor-free breathing air in dive centers, clean rooms, and emergency response units.

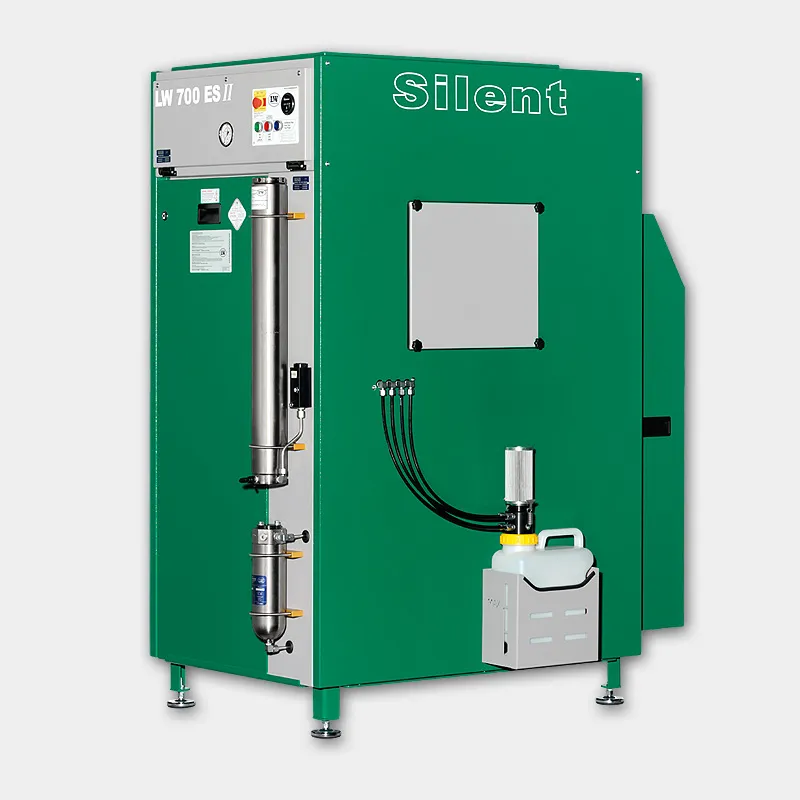

What Are the Functions of Moisture Separators and Air Dryers in Compressor Systems?

Moisture separators and air dryers reduce humidity to protect valves, pipelines, and breathing regulators from corrosion and freezing. Moisture separators also prepare air for chemical drying and purification processes that require dry air, such as hopcalite. Common types include:

- Cyclonic Separator directs airflow in a swirl to drop condensate.

- Refrigerated Dryer chills air to condense water for removal.

- Desiccant Dryer adsorbs residual moisture to below 2 ppm.

Effective humidity control prevents internal component damage and maintains reliable high-pressure performance across temperature extremes.

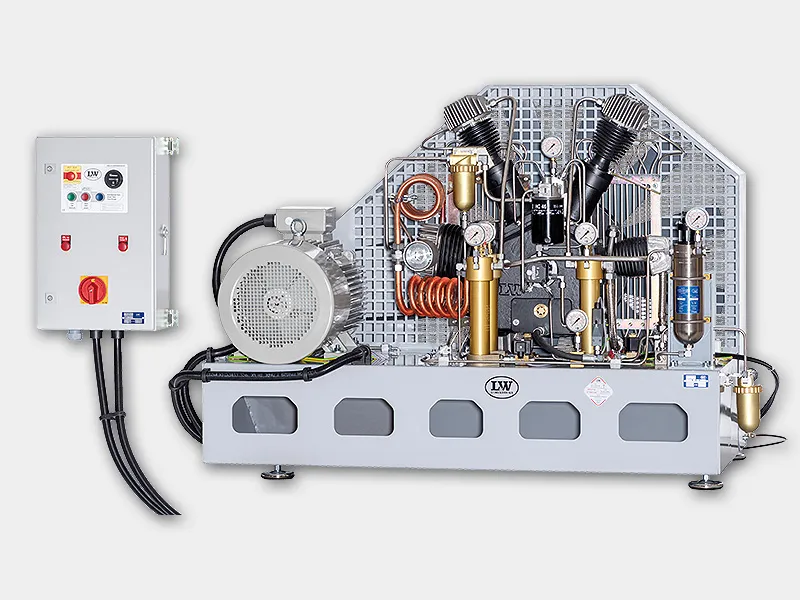

What Essential Safety and Control Features Ensure Reliable High Pressure Compressor Operation?

Safety and control features mitigate risks of over-pressurization, thermal stress, and component failure by monitoring critical parameters and executing protective actions. High-pressure relief devices, automated shutdown logic, and intelligent control panels form an interlocking system that prioritizes operator safety and equipment integrity.

How Do Pressure Relief Valves and Burst Discs Protect Against Over-Pressurization?

Pressure relief valves open at a predetermined setpoint to vent excess air, while burst discs rupture safely under extreme overpressure, preventing vessel failure. Core safety devices include:

- Spring-loaded Relief Valve activates at design pressure.

- Rupture Disc provides single-use emergency vent.

- Safety Manifold directs vented air away from personnel areas.

These mechanisms safeguard piping and storage vessels against catastrophic rupture and maintain compliance with ASME and ISO pressure vessel codes.

What Are Automatic Shut-off Systems and How Do They Prevent Damage?

Automatic shut-off systems use sensors to detect overtemperature, overcurrent, and pressure anomalies, triggering power cut-off and isolating the compressor. Trigger conditions include:

- High Discharge Temperature → Thermal sensor trips → Compressor stops

- Excessive Pressure Rise → Pressure switch opens → System vents to atmosphere

- Motor Overload → Current sensor trips → Drive disconnects

By halting operation when operating limits are exceeded, these features prevent equipment damage and prolong service life.

How Do Advanced Control Panels Monitor and Manage Compressor Performance?

Modern control panels integrate microprocessor-based logic, touchscreen interfaces, and network connectivity to track key metrics: pressure, temperature, runtime hours, and maintenance intervals. Common capabilities:

- Real-time Parameter Display enhances situational awareness.

- Fault Logging archives error events for diagnostics.

- Remote Communication enables predictive maintenance through IoT integration.

Intelligent monitoring supports data-driven decisions that maximize uptime and optimize lifecycle costs.

Which Performance and Efficiency Attributes Define Industrial High Pressure Compressor Features?

Performance metrics such as flow rate (CFM), discharge pressure (PSI/bar), energy consumption, noise level, and vibration are fundamental for evaluating compressor suitability. Efficiency technologies like variable speed drives, heat recovery systems, and precision manufacturing reduce operational expenses while maintaining required output.

How Are Flow Rate and Pressure Ratings Measured and Optimized?

Flow rate and pressure ratings are determined under standardized conditions—typically measured in cubic feet per minute (CFM) at specified PSI or bar. Optimization strategies include:

- Matching Cylinder Staging to Demand reduces wasted capacity.

- Variable Frequency Drives adjust RPM to actual airflow requirements.

- Intercooler Sizing lowers discharge temperature to boost volumetric efficiency.

Proper calibration of these parameters ensures supply exactly meets application demands without excess power draw.

What Energy Efficiency Technologies Reduce Operational Costs?

Advanced compressors incorporate several energy-saving innovations:

- Variable Speed Control adjusts motor loading to demand.

- Heat Recovery Modules repurpose waste heat for facility heating.

- Low-Friction Coatings minimize internal losses.

By capturing waste energy and optimizing drive performance, facilities can lower electrical consumption by up to 20 percent.

How Do Noise Reduction and Vibration Control Improve Compressor Usability?

Acoustic enclosures, anti-vibration mounts, and precision balancing reduce sound levels below 75 dBA and limit harmful vibrations. Key design elements:

- Sound-absorbing panels damp enclosure resonance.

- Rubber-isolated feet decouple vibration.

- Dynamically balanced rotors minimize mechanical noise.

Lower noise and vibration foster a safer environment and extend component longevity.

What Application-Specific Features Differentiate Diving, Firefighting, Industrial, and Medical Compressors?

Each industry imposes unique standards for air purity, pressure delivery, and system integration. Tailored features ensure compliance, reliability, and compatibility with specialized equipment—from dive banks and fire truck mounts to clean-room and surgical suites.

What Are the Unique Features of Diving Compressors for SCUBA and Technical Diving?

Diving compressors integrate cascade storage bottles, calibrated manifolds, and diver-grade filtration to supply breathing air up to 420 bar. Critical attributes include:

- Cascade Bank Configuration enables rapid fills and reduces start-stop frequency of compressor.

- Marine-grade Construction resists saltwater corrosion.

- Redundant Pressure Gauges ensure accurate staging.

These elements guarantee diver safety and efficient tank servicing in remote or high-use dive operations.

How Do Firefighting Compressors Meet Breathing Air Quality and Safety Standards?

Firefighting compressors deliver oil-free air with integrated CO monitors and onboard purification to comply with NFPA 1989. Typical specifications:

- In-cabinet Filtration ensures rapid deployment.

- CO Scrubbers prevent toxic gas contamination.

- Portable Power Options support mobile operations.

Meeting these standards safeguards first responders and aligns with municipal safety regulations.

How Are Industrial High Pressure Air Systems Customized for Manufacturing Needs?

Industrial systems feature modular compressor skids, remote monitoring, and automated condensate management to integrate with production lines. Customization options include:

- Multi-unit Sequencing ensures continuous supply.

- PLC Integration provides automated process control.

- Expanded Receiver Capacity smooths pressure fluctuations.

Tailored designs optimize uptime for stamping presses, laser cutting, or pneumatic conveying.

What Medical Air Compressor Standards Ensure Purity and Reliability?

Medical air compressors must comply with ISO 8573-1 Class 0 (oil-free) and NFPA respiratory gas purity requirements. Comparative standards include:

Best Practices for Medical-Grade Compressed Air

This resource outlines the critical requirements for medical-grade compressed air systems, emphasizing compliance with standards such as NFPA 99. It details the necessity for continuous operation, redundancy, and specific purity levels for medical air, including limits on liquid hydrocarbons, gaseous hydrocarbons, and particulates, as mandated by NFPA 99 and the United States Pharmacopeia (USP).

JHFoster, 2025

This citation verifies the stringent purification and safety standards required for medical air compressors, directly supporting the article’s discussion on advanced air purification and application-specific features for medical compressors.

How Do You Choose the Right High Pressure Air Compressor Based on Key Features?

Selecting a compressor demands careful evaluation of operational requirements, environmental constraints, and service support. A structured approach ensures alignment with performance goals, budget, and regulatory demands.

What Checklist Should You Use to Evaluate Compressor Specifications?

Use the following criteria to compare models and manufacturers:

- Maximum Pressure Rating and Flow Output

- Motor Type and Power Efficiency

- Filtration Stages and Purity Class

- Safety Devices and Control Logic

- Noise, Vibration, and Enclosure Design

- Maintenance Access and Service Network

- Online Maintenance, Service and Repair Support

Evaluating these factors side by side simplifies decision-making and highlights hidden cost drivers.

How Do Application Requirements Influence Compressor Selection?

Different end-use scenarios dictate feature priorities:

- SCUBA Filling demands high peak pressure and cascade storage.

- Fire Services require rapid-deployment, self-contained units.

- Manufacturing needs constant flow and remote auto-management.

- Medical Facilities insist on oil-free, ultra-pure air.

Mapping system features to operational contexts prevents overspecification or underperformance.

When Is a Custom High Pressure Compressor Solution Necessary?

Custom compressor solutions become essential when standard models cannot meet unique specifications—such as subsea gas injection at extreme depths or specialized industrial processes requiring non-standard pressures. Tailored designs allow integration of exotic materials, bespoke control algorithms, and dedicated support packages that maximize uptime in critical environments.

What Are Common Maintenance and Troubleshooting Practices for High Pressure Air Compressors?

Routine service and prompt troubleshooting extend system life and prevent costly downtime. Consistent attention to filters, lubricants, and mechanical seals keeps performance at peak levels, while a structured fault-diagnosis workflow accelerates problem resolution.

How Often Should High Pressure Compressors Be Serviced for Optimal Performance?

Service intervals vary by duty cycle and operating conditions, but typical schedules include:

- Filter and Separator Replacement vary by model, size and environmental conditions

- Oil Change and Seal Inspection intervals range from 100-200 hours

- Full overhauls average 4000-6000 hours

- Valve refurbishments or exchanges typically occur at 1,000-, 2,000-, or 4,000-hour intervals, depending on the stage

Adhering to these intervals reduces the risk of unplanned shutdowns and preserves efficiency.

What Are Typical Issues and How Can They Be Troubleshot Effectively?

Common compressor issues include leaks, pressure loss, and thermal overload. Effective troubleshooting steps are:

- Inspect and tighten flange and hose connections to stop leaks.

- Verify intake filter element integrity and replace if clogged.

- Monitor discharge temperature and check cooling system function.

Swift corrective actions minimize downtime and repair costs.

How Does Proper Filtration System Maintenance Impact Compressor Longevity?

Regular filter changes and separator drains prevent moisture and debris from entering compression stages, reducing internal corrosion and wear. Clean filters maintain optimal airflow and pressure delivery, supporting consistent performance and lowering replacement expenses for critical components.

Routine inspections and adherence to service schedules ensure that high pressure air compressors remain safe, efficient, and ready to support critical applications across industries. Contact LW Americas to explore custom high‐pressure solutions backed by decades of expertise and comprehensive global support. Our specialists will guide you through feature selection, system integration, and lifecycle management to maximize your investment.

Frequently Asked Questions

What are the key safety features to look for in high pressure air compressors?

When selecting a high pressure air compressor, essential safety features include triple-media purification systems, pressure relief valves, automatic shut-off systems, and thermal overload protection. Pressure relief valves vent excess air to prevent over-pressurization, while automatic shut-off systems detect anomalies and halt operation to avoid damage. Additionally, thermal overload protection monitors temperature levels, ensuring the compressor operates within safe limits. These features collectively enhance operator safety and equipment reliability, making them critical considerations in your purchasing decision.

How can I improve the energy efficiency of my high pressure air compressor?

Improving energy efficiency in high pressure air compressors can be achieved through several strategies. Implementing variable speed drives (VSDs) allows the compressor to adjust its motor speed based on demand, reducing energy consumption. Regular maintenance, such as replacing filters and ensuring proper lubrication, also plays a vital role in maintaining efficiency. Additionally, incorporating heat recovery systems can repurpose waste heat for other processes, further lowering operational costs. These measures not only enhance performance but also contribute to sustainability efforts.

What maintenance practices are essential for high pressure air compressors?

Regular maintenance is crucial for the longevity and efficiency of high pressure air compressors. Key practices include routine inspection and replacement of filters, checking oil levels, and monitoring for leaks. It’s recommended to change filters based upon environmental conditions and perform oil changes every 100-200 hours. Additionally, conducting a full overhaul every 4,000 hours ensures that all components are functioning optimally. Keeping a detailed maintenance log can help track service intervals and identify potential issues before they escalate.

How do I determine the right size compressor for my application?

Choosing the right size compressor involves assessing your specific air demand, which is typically measured in cubic feet per minute (CFM). Calculate the total CFM required by considering all tools and equipment that will be used simultaneously. Additionally, factor in the desired pressure level (PSI or bar) for your application. It’s advisable to select a compressor that can provide slightly more capacity than your calculated needs to accommodate fluctuations in demand and ensure optimal performance. LW Americas reccomends evaluating estimated use and resulting annual run-time to meet an antitipated overhaul at year five or later. Please reach out to a LW Americas professional for assistance.

What are the implications of using a compressor that does not meet industry standards?

Using a compressor that does not meet industry standards can lead to serious implications, including safety hazards, equipment failure, and regulatory non-compliance. For instance, in medical applications, non-compliant compressors may produce or fail to eliminate contaminated air, posing health risks. In industrial settings, inadequate pressure or purity levels can disrupt operations and lead to costly downtime. Additionally, failure to adhere to standards can result in legal liabilities and damage to a company’s reputation. Therefore, ensuring compliance is critical for operational integrity.

What role does air quality play in the selection of high pressure compressors?

Air quality is a crucial factor in selecting high pressure compressors, especially for applications in medical, diving, and firefighting sectors. Compressors must meet specific purity standards to ensure the safety and effectiveness of the compressed air. For example, medical-grade compressors must comply with ISO 8573-1 Class 0 standards, which dictate oil-free

air. Inadequate air quality can lead to health risks, equipment damage, and operational inefficiencies. Therefore, understanding the required air quality standards is essential for making an informed choice.

Conclusion

Choosing the right high pressure air compressor is essential for ensuring operational efficiency, safety, and compliance across various applications. By understanding key features such as filtration, safety controls, and performance metrics, businesses can make informed decisions that align with their specific needs. Regular maintenance and expert guidance further enhance the longevity and reliability of these systems. Contact LW Americas today to discover tailored high-pressure solutions that meet your unique requirements.